Metal Glue Guide – Complete Gluing Guide for all Metals

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

There are different methods of joining metal together. The most common one is probably welding. Gluing metal is not yet familiar to many small users, but this method is becoming more and more common in both domestic and industrial applications. Why metal gluing is becoming more and more popular, what you need to keep in mind, and why metal glues need to be heat-resistant can be found in our glue guide.

Table of Contents

- What Is Metal Glue?

- Important Questions Before Choosing a Metal Adhesive

- Advantages and Disadvantages of Metal Bonding

- An Overview of the Different Metal Adhesives

- Practical Applications of Metal Adhesives

- Adhesive for Metal on Other Materials

- How to Glue Metal

- Safety Instructions for Gluing Metal

- Frequently Asked Questions

What Is Metal Glue?

When talking about the different ways of joining metals, most people immediately think of welding. However, there are also other joining methods such as riveting.

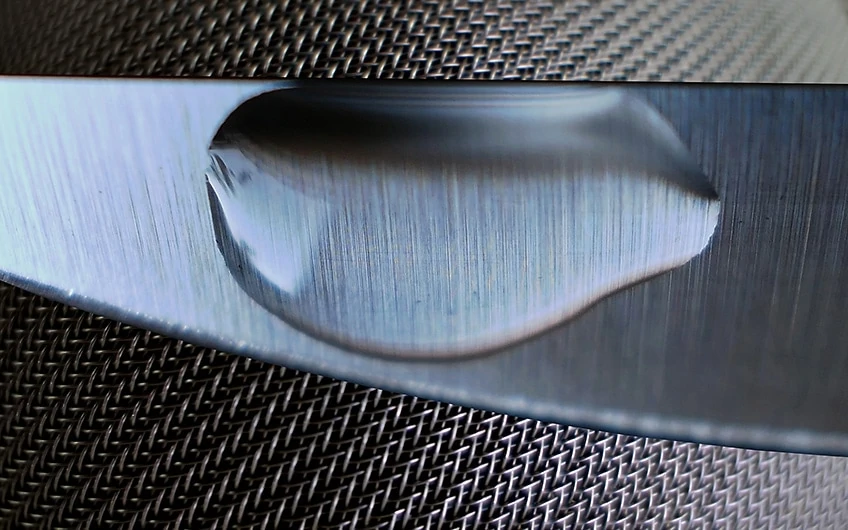

Nowadays, a modern joining method is becoming more and more popular: bonding metal. This often requires a highly innovative metal adhesive, because joining metals presents the user with very specific challenges.

So you cannot just use any glue; as we said, it has to be a special glue for metal. Furthermore, there are several aspects to consider. We will explain which these are below.

Important Questions Before Choosing a Metal Adhesive

Before gluing metal you should ask yourself the following questions:

- What type of metal do you want to join? It makes a difference whether you want to glue aluminium or cast iron, for example. You must also consider the material of the second substrate, i.e. the second surface to be bonded. You can bond metal to metal or join different materials. However, you may need a different adhesive for this.

- Which surface structure does the material to be bonded have? In the case of aluminium, for example, you have to allow for the recurring oxidation of the surface. Other metals have a rather smooth or slightly rough surface. It may also be necessary to even out unevenness.

- How large is the area to be bonded and what is its geometric shape?

- What is the time window for curing the adhesive and what are the processing specifications?

- What is the load to which the bond will be subjected and where will the bond be used later?

- Are the surfaces provided with any coating?

You should pay attention to these questions before you buy an adhesive for metal, because they are extremely important for an optimal adhesive bond.

Advantages and Disadvantages of Metal Bonding

Bonding metal has a number of advantages which could be of particular importance for the small user:

PROS

- No heavy equipment is required for metal bonding, but in principle only the parts to be joined, the adhesive and sandpaper.

- The metal adhesive can be easily applied without any great previous knowledge – this is quite different with soldering or welding. There is a lot that can be done wrong, so it is usually more appropriate for the do-it-yourselfer to glue the materials instead of welding.

- When bonding metal there is a significant time saving compared to welding or even riveting, soldering or screwing. Only the drying phase of the adhesive for metal should be considered.

- Metal bonding does not result in unsightly welding seams, especially if the user ensures a clean connection and thoroughly removes adhesive residues.

- Of course, the question of cost also plays a role: bonding metal is relatively inexpensive. This applies even if you use a high-quality metal adhesive.

CONS

- An adhesive bond never penetrates the surface of the material, i.e. the material is not joined as durably and resiliently as by a joining technique such as screws or rivets. Welding also produces a far more durable connection than metal gluing.

- Some types of adhesives and substances used for surface preparation, such as primers, are subject to the Ordinance on Hazards and should only be used with protective equipment.

An Overview of the Different Metal Adhesives

A good metal adhesive should have different characteristics. It is important that the metal adhesive:

- Is heat-resistant;

- Is impact-resistant as well as temperature- and weather-resistant;

- Is fileable and drillable;

- Is resistant to chemicals; and

- Is resistant to ageing processes.

There are various adhesives available for metal that have these properties:

- Epoxy Adhesives are adhesives based on epoxy resin. They are used in particular for bonding costume jewellery or in wood processing. But they are also very suitable for metal bonding.

- Polyurethane Adhesives offer the user all the advantages of the very resistant material PU. This is not only UV-resistant and therefore resistant to yellowing, but also water-resistant and can therefore be used well in outdoor applications.

- In principle, Superglues are part of the standard equipment of every household and are suitable for almost all types of bonding. Their great advantage is the extremely fast curing. They bond metal very firmly and permanently, but are generally only suitable for small areas and spot gluing.

A further distinction is made between one-component and two-component metal adhesives. Single-component adhesives are not only used to join the substrates, but also for sealing and filling. Therefore they are also called hybrid adhesives. They are applied in larger quantities than two-component adhesives and cure more elastically. For this reason, they are particularly suitable for bonding iron, as iron shows different thermal reactions in different situations – it therefore has a distinct coefficient of expansion.

General Metal Adhesives Based on Epoxy resin

An extremely durable and durable adhesive for metal is an epoxy resin based adhesive. It consists of two components which only react with each other when they are mixed. The user can make this mixture himself. In the meantime, however, double-chamber cartridges are also available, with which mixing is conveniently dispensed with.

Epoxy resin adhesives are highly variable adhesives that can in principle take on all properties that are useful to the user: They are available as slow or fast drying adhesives, they can be flexible or non-flexible. It is also possible to add various additives such as colorants and fillers; however, curing is normally either black, gray or transparent. They are highly resistant to temperature and impact and are therefore also suitable for heavy loads.

Special adhesives for epoxy-based metal are particularly suitable for non-ferrous metals, which generally present a challenge in bonding work.

Liquid Metal Based on Epoxy Resin

If you want to glue stainless steel or other metals, you need a very powerful adhesive. You will find this in liquid metal, for example from the company Petec. It is not only temperature-resistant up to 120° Celsius, but also perfectly fills up false holes, blowholes and holes when used as a filler. It can be used to carry out all kinds of repair work on different materials. It unfolds its full adhesive potential, especially if you want to glue cast iron or other metals like stainless steel, aluminium or different alloys.

Polyurethane Adhesives for Bonding Metal

The Polyurethane Adhesive for metal is very suitable for permanent repairs around the house. This metal adhesive is heat, UV and water resistant and therefore perfect for outdoor use. It never becomes brittle and cures very quickly. A mechanical treatment after drying is possible as well as painting and varnishing.

Superglue

The superglue guarantees a very strong and durable connection even of metals. If you glue metal to metal and only want to make a small bond, superglue is often the first choice. Its curing phase is extremely short. But this is also a disadvantage, because superglue is not suitable for two-dimensional connections. Therefore it is only used for spot gluing.

Strong Alternative: Wrought Metal

If you want to glue stainless steel or other metals and need a very strong adhesive strength, you have come to the right place with epoxy putty. Here we can make a clear recommendation for the modelling clay of the company QuikSteel. This is not only one of the most adhesive sealing and bonding compounds currently on the market, it is also easy to use.

In addition, it enables the user to carry out simple repairs on the side, for example when a metal part of the bicycle needs to be repaired quickly during a bike ride. The QuikSteel wrought metal deserves its name rightly because it can be pressed together like plasticine and pressed into the area to be repaired. The wrought metal has an extremely strong adhesive potential and can be applied to many different materials. After it has hardened, it can be easily processed mechanically.

Practical Applications of Metal Adhesives

Metal adhesives can be used for a variety of connections and are ideal for very stable bonding. So if you are on the road with your bike, you should always have a tube of superglue in your pocket – with this you can repair metal parts on your bike perfectly.

A good metal adhesive is also perfect for cracks in the bumper. In general it is suitable for all metal parts, but also for many plastic parts on the car. With the right metal adhesive, all repair work around the car becomes child’s play. You can easily repair headlight holders and body parts. The following properties of the metal adhesive are of great importance when used on the car:

- Resistance to petrol

- Heat resistance

- Oil resistance

As for other properties, these vary. Some types of adhesive are flexible, others are high-strength. So you should find out which adhesive is suitable for your type of application before you start repairing.

But the metal adhesive is not only suitable for use on damaged metal parts. Do your children rarely handle their toys with care? Even the repair of broken toys is no problem with the right metal adhesive, as it is not only suitable for metal, but also for many other materials.

Adhesive for Metal on Other Materials

Adhesives for metal based on epoxy resin can not only be used for metallic objects. Although you can easily glue cast iron or other types of metal with them, the adhesive also works wonderfully with different materials. So it can be used for

- Wood

- Ceramics

- Glass

- Porcelain

- Stone

- Various types of Plastic

However, you must pay attention to the different surface conditions. If, for example, you want to glue metal to wood, you have to consider the porosity of one material and the smooth surface structure of the metal.

How to Glue Metal

In the following we would like to give you a good starting point for your work with our metal bonding step-by-step guide.

Preparation Work

Before you start the actual bonding process, the surface of the substrates must first be prepared. This is particularly important for metal bonding, as this material is often used in areas where it is exposed to high mechanical and thermal stress. If the adhesive properties of the adhesive have previously been negatively affected by inadequate cleaning of the substrates, the bonded areas may break.

So clean the surfaces thoroughly from all deposits. These are:

- Oils

- Greases

- Dirt

- Dust

- Sealants

- Adhesive residues from older bondings

- Grate

Care should be taken when working with bare fingers, as the grease on the skin can also impair the adhesive effect as a deposit. We recommend that you wear gloves.

Rust must be thoroughly removed before the gluing process. This can be done by grinding or sandblasting. The dust produced should then be removed again. To improve the adhesive’s bonding properties, the substrates should be roughened afterwards. This can also be done by grinding or sandblasting. However, it is essential to clean the substrates before sanding or sandblasting, as otherwise the dirt will be introduced into the surface and can massively impair the adhesive’s adhesive properties.

A wide range of products is available for cleaning oil, grease and sealants. There are special cleaners in all imaginable variations. An HG-Cleaner can be of great help here and is usually also recommended by adhesive manufacturers.

The Actual Bonding Process

Once the adhesive surfaces have been thoroughly cleaned, you should allow the substrates to dry completely. Now the special adhesive for metal can be applied. Pay attention to the manufacturer’s instructions. Depending on which metal adhesive you use, you must apply it either on one or both sides and possibly observe the flash-off time. After the adhesive has been applied, the substrates are firmly joined together and possibly fixed. This also depends on the adhesive used. For example, metal epoxy-based adhesives should be held together for about sixty minutes with firm pressure. Excess adhesive can be removed with acetone.

Curing and Loading the Joints

Also follow the adhesive manufacturer’s instructions regarding the curing time. Superglue only requires a very short drying phase, while other metal adhesives, such as epoxy adhesives, take up to twenty-four hours to cure. If in doubt, leave the joined parts to dry longer. Afterwards they are fully loadable and can usually be machined.

Rework

After complete curing, the material can be further processed as required. You can work on it mechanically, e.g. sanding and drilling, but you can also paint or lacquer it.

Safety Instructions for Gluing Metal

When working with metal adhesives you should pay attention to your safety. This is especially true when working with epoxy and polyurethane adhesives. The working area should be well ventilated and your mucous membranes should be protected from escaping vapours. Always wear gloves so that your skin does not come into contact with the powerful metal adhesive. The first choice should be gloves made of nitrile, not cotton or PVC, as nitrile is more resistant to most chemicals.

Please also observe the manufacturer’s instructions on processing. If your mucous membranes or eyes come into contact with the adhesive, wash them thoroughly with warm water for several minutes and consult a doctor immediately. When doing so, you should carry the adhesive packaging with you so that the doctor can get an idea of the ingredients.

Frequently Asked Questions

What Is the Best Glue for Metal?

This question cannot be answered conclusively as it depends on various factors. For example, it depends on the metal to be bonded, the intended use, and the thermal and mechanical loads that the bonded seam must withstand.

How Well Does Metal Adhesive Hold?

Correctly applied and matched to the respective metal, a high-quality metal adhesive forms a very strong and durable bond. However, this will never be as strong as the connection made by a classic mechanical joining technique such as welding.

Finding the right metal adhesive is not as easy as it seems. There are many different aspects to consider. However, once you have found the optimum adhesive for metal, the actual bonding process is child’s play. We hope we were able to help you.