What Is PVA Glue? – Learn All About Polyvinyl Acetate Adhesives

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

In recent decades, we have made leaps and bounds in the quality, variety and versatility of adhesive products. From epoxy to waterproof sealants, there is an adhesive for pretty much every application under the sun. However, one glue that has proven to be quite versatile and cost-effective is PVA glue. This white sticky substance has been around since most of us were in kindergarten, so let’s have a look at exactly what PVA glue is, how it’s made, what exactly goes into it, and whether or not there are different types of PVA glue out there.

Table of Contents

What Is PVA Glue?

Pretty much everyone on the face of the planet has used or come into contact with PVA glue. What is PVA glue though? Put simply, PVA adhesive is a thermoplastic that allows you to adhere one material to another. Thermoplastic adhesives work by hardening when exposed to a temperature change, either colder or warmer than the temperature they’re meant to be stored at.

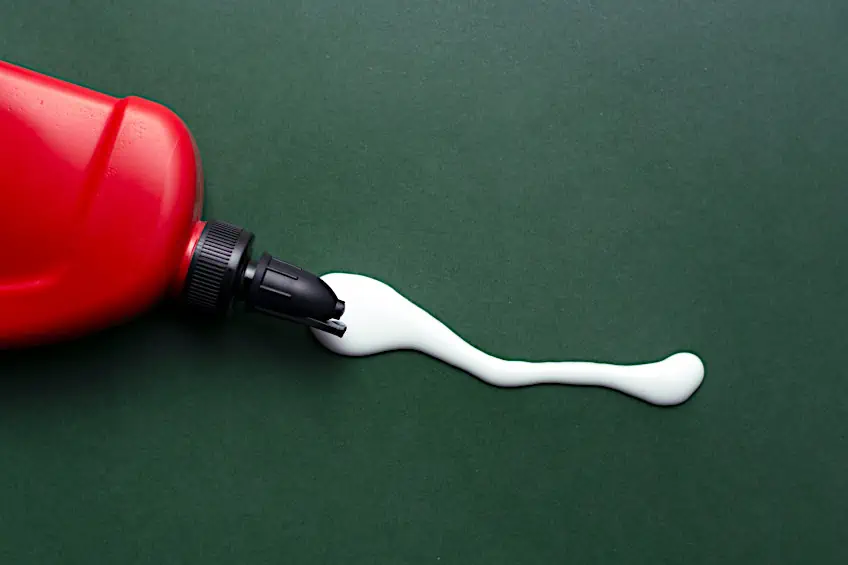

PVA glue is typically white in color and has a runny consistency compared to similar adhesives. PVA belongs to a group of thermoplastic substances that have come to be known as polyvinyl esters that are capable of gluing a number of common materials together. PVA glue is one of the most widely used adhesive types around the world, being used in various industries and applications.

PVA glue’s primary component is polyvinyl acetate, a substance that is common in a number of off-the-shelf adhesives, that can be used to repair and join everyday materials. You probably know PVA glue as wood glue, paper glue, white glue, kids, glue, or school glue. While you might consider PVA to be inferior to more high-end adhesives, in sufficient quantities and potency PVA adhesive can rival industrial-strength adhesives!

The cool thing about PVA glue is that it is completely water-soluble and can be used safely by kids and adults alike without having to worry about toxicity and/or respiratory problems arising. Since most PVA glues are inexpensive, versatile, safe to use, and can be bought pretty much anywhere, they are quite popular, even with the advent of objectively superior adhesives.

The History of PVA Glue

While it is used widely today, PVA glue isn’t a new invention. PVA glue was originally developed by Dr. Fritz Klatte in Germany all the way back in 1912. The uses for PVA glue were immediately apparent to most people. PVA glue has been around for just over 100 years, and it doesn’t seem that it will be going away any time soon. Instead of moving away from this glue toward other adhesive compounds, many companies have sought to improve the adhesive abilities of this wood and add other characteristics to it such as improved drying times, water resistance, as well as resistance to impact and abrasion

There are many reasons that this particular adhesive grew and maintained its popularity throughout the world. For one, it’s quite easy to make PVA glue even if you don’t have a lab full of chemicals. It’s also really cheap to both make a buy, in combination with its overall effectiveness as an adhesive.

Before the advent of PVA glue, the majority of the glue used at the time consisted of animal hide glue. What exactly is animal hide glue? Well, as the name suggests, animal hide glue is made from the processed hide of various animals. Today, this type of glue is most commonly used to repair antique furniture, especially ones of the high-end variety.

Different Types of PVA Glue

Like pretty much every other adhesive on the market there are many types of PVA glue available. Different types of PVA glue are manufactured for different applications, usually to fulfill different purposes or withstand different forces. All of them are made of what is essentially the same core compound though, so let’s have a look at a few of the most common PVA glue variations you have available to you.

White Glue

White glue is by far the most common PVA glue type. Known by most use as school glue or kids’ craft glue, this adhesive is a classic example of how simple and effective PVA glue can be without any additional additives. While this glue is inexpensive it is also quite good at adhering to a number of surfaces with little to no preparation needed.

How exactly does white glue work though? Put simply, white glue works by seeping into the pores of a material while using surface friction to create a bond between it and the surface. Once the glue begins to harden it will change from a stark white color to an opaque clear color, becoming unnoticeable if the glue is applied discreetly.

Wood Glue

PVA wood glue is another adhesive that has commonly been described as white glue. Wood glue has been used for quite a long time and has become the go-to glue for budding wood crafters and seasoned professionals alike. If you need to quickly join two pieces of wood or implement a quick repair, this is the glue most crafters turn to.

Like white glue, this glue is white while still inside the container. However, once wood glue is applied to a surface it tends to create a superior bond to white glue, not only seeping into the pores of a wood board but also bonding with the wood fibers to a degree. This ensures superior adhesion in addition to being able to bear weight and be sanded once dry.

How strong is wood glue exactly? Well, if used correctly it is often said that the wood will break before the joint does. This might seem excessive, but if wood glue is applied correctly and allowed to set under pressure (through the use of clamps) it is entirely possible for the bond to be superior to the integrity of your wood board.

Another important characteristic of this glue is that it is considered to be waterproof. While most wood glues are resistant to water, not all are, so ensure that your wood glue is waterproof and not just water-resistant if you intend to use your workpiece outdoors.

Water-Resistant Glue

While most wood PVA wood glue products are somewhat water-resistant, there are dedicated formulas for water-resistant and waterproof PVA glues. If you’re not sure what the distinction is, water-resistant glue can be exposed to condensation and steam for limited periods without the adhesive bond being affected, whereas waterproof glue can be completely submerged without the bond being affected at all.

Water-resistant PVA glue is usually used when the application of the workpiece will involve being in a somewhat moisture-rich environment where concerns of mildew and rot might come into play. Water-resistant PVA is capable of shedding this moisture with ease, and will not allow the wood to rot or warp in the area where the glue has been applied.

How do you know if your glue is water-resistant or waterproof? The only way to be sure is to test it but in most cases, the container should clearly state whether the glue is water-resistant or waterproof. If you’re still unsure, either test the glue on some spare material or simply contact the manufacturer.

What Are the Key Ingredients of PVA Glue?

As we mentioned previously, PVA glue is a relatively simple composition of elements that makes for quite an effective wood glue. What exactly does it consist of though? PVA primarily consists of acetic acid and some ethylene, but there are some types of PVA glue that are made of more renewable and environmentally sustainable components.

Modern sustainable glues can consist of a lot of anything from milk to vegetables, to animal blood, and even the skin of rabbits and gelatine! There are others that can be made of the gum from certain trees too, which not only reduces greenhouse gasses produced in their production but also shifts the production of a much-needed resource to sustainable materials.

Key Properties of PVA Glue

There are many properties that make PVA glue both unique and much like other types of adhesives available today. One of its defining characteristics is that it is best suited for use on highly porous materials while being marginally less effective when used on sheer surfaces or materials with low porosity. This is because PVA works by being absorbed into these materials instead of just clinging.

PVA is also quite easy to remove compared to other off-the-shelf adhesives. How is this possible? Well, PVA glue is water-soluble, meaning that if it’s spilled or needs to be removed, you can simply get some soap and water, use some elbow grease, and remove the glue completely. This is pretty cool considering that many other adhesives require the use of solvents to be removed.

PVA glue is also pretty safe. This is part of why it happens to be so popular compared to many other adhesives. After all, kids use PVA glue in school all the time, and this is because they’re very much non-toxic. PVA glue doesn’t contain any chemicals that could cause discomfort if the fumes are inhaled or should some accidentally come into contact with your skin.

PVA is also popular because of how malleable it is. PVA glue, both when wet and dry, can be manipulated to a degree that many other adhesives simply cannot. PVA glue can be bent when dry, and can even be sanded if need be. In addition to being sandable and flexible, PVA glue also dries clear, making it less of an eyesore if visible and/or overapplied.

What Is PVA Glue Used For?

As we mentioned previously, PVA glue is extremely popular and has been used in a wide variety of applications in a number of industries all over the world. What is PVA glue used for exactly? There are plenty of uses for PVA glue, so let’s have a look at a few of the most well-known uses for this adhesive and why it tends to be a better fit compared to other adhesive types.

Woodworking

Woodworking is one of the most common applications of PVA glue. PVA wood glue can be found in pretty much any wood crafting environment where it is generally used to secure, join, or adhere one workpiece to another, or to join a workpiece to another surface. Why is PVA so commonly used in woodworking environments though?

Well, it’s easy to use. PVA glue simply needs to be applied to the surface and then secured with some woodworking clamps and left to dry. There’s no need to mix anything together or apply heat, saving you time and effort when working on a project. It also doesn’t produce an odor, contains no VOCs (volatile organic chemicals), dries quickly, and is able to be sanded once dry.

Paper and Cardboard Production

PVA glues and/or glues that contain PVA are used widely and quite often in the paper and cardboard container production industries. Why? Well, pretty much for the same reasons that it’s used in the woodworking industries. Paper and cardboard sometimes require the use of strong, non-toxic adhesive to ensure that they retain a certain shape while they’re in use or being sold.

Somewhere where you might not expect to find PVA glue that involves the use of paper and cardboards is the production of books and their covers. PVA glue is commonly used to bind books to their covers, particularly paperback books as hardcovers are sometimes bound with twine and/or various other means.

Textiles and Clothing Production

One industry that you might not expect to find PVA glue being used is the textiles and clothing industry. It might seem strange at first, but the more you think about it the more you’re likely to realize that this industry more than any other needs things to be adhered together quickly and easily, which is where PVA glue comes in.

PVA glue can be used to paste things like paper and cardboard on the surface of a fabric, which is an idea if you’re trying to transfer a design onto the surface of a fabric workpiece or if you need to adhere two pieces of fabric to one another. This is pretty common in furniture production, where waterproof PVA glue is used to permanently or semi-permanently adhere pieces of fabric together.

PVA glue is sort of the ideal adhesive to use for fabric considering that it is not non-toxic and does not interact negatively with the fabric. Aside from being used in the production of clothing and textiles, it can also be used in DIY alterations to existing clothing, or to repair clothing even if it’s just in a temporary sense.

Crafting

Even if the only experience you’ve had with PVA glue is in kindergarten, most people associate this type of glue with use in crafts and DIY, which makes sense considering that most beginner crafts involve the use of PVA glue in their construction. It makes even more sense when you consider that PVA glue is super versatile and can be used to adhere many different materials to one another.

There are many, many different types of PVA glues for crafting. Whether you’re working with plastic, cardboard, paper, resin, wood, and even felt, there is a PVA glue for your crafting niche. There are other types of crafting glue available too, but people tend to gravitate toward PVA glue because of its accessibility and versatility.

PVA glue is also able to be used on the spot and it dries quickly. Unlike epoxy which needs to be combined and allowed to dry and cure for 24 hours, PVA glue can be applied instantly with little preparation and only takes a few hours to dry completely, at which point your workpiece should be completely ready for use.

Advantages and Disadvantages of PVA Glue

Unfortunately, just like any other adhesive on the face of the planet, PVA glue is not perfect. While there are many advantages to using this type of glue there are also some notable disadvantages you should take into account before committing to using PVA glue for your next woodworking or crafting project. So, what are the advantages then? PVA glue is versatile, fast drying, easy to use, hard wearing, can be sanded, can be bent and retain its shape, dries almost completely clear, and can be purchased pretty much anywhere (both in-store and online). It is also one of the safest and most child-friendly adhesives out there.

There are some other disadvantages of white glue too. PVA glue is more of a light-duty glue compared to some of the more robust adhesives on the market. For one, when PVA glue is applied to join two workpieces together, the workpiece needs to be clamped together to ensure that the glue dries correctly. Some PVA glues can also take a bit longer to cure completely, sometimes as long as 24 hours, which isn’t ideal in time-sensitive scenarios.

PVA glue also has a limited shelf life. This means that even though it’s readily available, if it isn’t purchased and used the bonds that make up the glue will break down, making it objectively useless. Additionally, not all PVA glues are water-resistant or waterproof, which can be a bit frustrating considering that it can be challenging to find a completely waterproof version. That being said, most crafters feel the disadvantages of white glue don’t outweigh its advantages and convenience.

- Versatile

- Easy to use

- Readily available

- Can be sanded

- Can be bent and retain its shape

- Dries quickly

- Dries clear

- Needs to be clamped to work as intended

- Can take a long time to cure

- Limited shelf life

- Not all variations are waterproof/water resistant

Tips for Using PVA Glue

Now that you know a bit about glues that contain PVA, we thought we’d show you how to use it. Using PVA glue is pretty straightforward but there are a few tips and tricks you can use to ensure that your workpiece receives the glue correctly and that the bond is secure. Always ensure that your workpiece is properly prepared and that you have the correct glue before applying it.

Do Your Best to Spread the Glue Out

The best way for you to ensure that your workpiece is properly glued together is to spread the PVA glue out over the surface of your workpiece. Using a brush, gently and evenly apply your glue to the entire surface using a brush. Do not over-apply the glue in a single area or it will ooze and/or squirt out once the second part of your workpiece is clamped down.

Ensure That Your Workpiece Is Clamped

Unfortunately, PVA will not work effectively unless the two surfaces you are trying to join have been clamped together while the wood dries. PVA glue requires pressure to ensure that the wood dries and is absorbed into the pores of the surface, so it’s best to use a dedicated clamp or any object with sufficient weight to ensure that the wood will be able to dry correctly.

Wait for Your Glue to Dry Completely

While PVA glue does dry very quickly it’s best to always wait for the manufacturer’s recommended time period before attempting to make use of your workpiece. How long does PVA glue usually take to dry? Well, it can take anywhere between three to 12 hours for glues that contain PVA to dry completely.

Now that you know what PVA glue is, how it is made, what it is made of, what it is used for, and how to use it effectively, it’s time for you to get out there and put your newfound knowledge to the test! Remember to ensure that you have the right type of PVA glue for your intended application, and that you follow the manufacturer’s instructions as closely as possible.

Frequently Asked Questions

What Does PVA Stand for in Glue?

PVA glue is pretty common, but what does PVA stand for in glue? PVA glue stands for polyvinyl acetate. This is the primary element of these types of glues, of which there is a wide variety for different applications.

Is PVA Glue Waterproof?

While not every PVA glue is waterproof, many of them are water-resistant. The difference between the two is that waterproof glues can be submerged, while water-resistant glues can only be exposed to water and/or moisture for limited periods of time.

What Do You Use PVA Glue For?

What can PVA glue be used for? PVA glue can be used for a variety of applications, including the creation of crafts, fabrics, furniture, and even the creation of books! PVA glue is extremely versatile but does lack durability.