Best Wood Glue – A Guide on the Best and Strongest Wood Glue

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Wood is not one of the most popular materials for nothing, because it has a variety of positive properties. However, it also has some disadvantages, which can affect its level of adhesion. In our wood guide, you will learn how you can use glue for wood and what the best wood glue is for this purpose.

Table of Contents

Properties of Wood

If you want to combine wood and glue, you need to consider some basic things, because not all wood is the same. There are a large number of different woods, which are distinguished not only on the basis of their hardness – soft and hard – but also on the basis of their color or possibly existing resin ducts. Furthermore, there are solid woods as well as heartwood, chipboard, or sapwood. A distinction is also made between swelling and porous woods.

But that is not all, because the properties of the respective wood can even vary depending on humidity, temperature, and other environmental conditions. It expands and contracts, where the wood is said to “work”. This working can lead to the glued seam being damaged over time and, in the worst case, cracking if the adhesive is not suitable.

Furthermore, a good wood adhesive must also be able to bond different materials together, such as when different coefficients of thermal expansion are present. A good wood glue must take all of these properties into account, because it must provide sufficient adhesive force without causing the wood to swell or be absorbed by it.

Overview of Different Stress Groups

To join wood permanently and with high strength, the adhesive must have the optimum properties for the particular bonded joint. For this reason, wood adhesives are divided into four different stress groups. The higher the class designation, the more weather-resistant the respective wood glue is.

So, if you want to glue wood, you should definitely pay attention to the stress group, because otherwise it could happen that the glued seam comes loose again in unfavorable weather conditions outdoors. In principle, any stress group is suitable for indoor use, while only stress group D4 is suitable for a really strong bond outdoors.

For outdoor use, you should also pay attention to the temperature resistance of the wood glue. It is advisable to use a white glue that can also compensate for larger temperature differences and direct sunlight.

The classes D1 to D4 are used for the stresses, as shown in the following table.

| Classification | Features |

| Stress Group D1 |

|

| Stress Group D2 |

|

| Stress Group D3 |

|

| Stress Group D4 |

|

Different Types of Glue for Wood

There are different types of wood glue on the market and not all of them are suitable for every application. As already explained, there are those for indoor use as well as those for outdoor use. But other criteria are also important if you want to glue wood.

For example, wood glues with natural ingredients are distinguished from those that contain synthetic substances. Natural wood glues are:

- Glutin glue, which contains animal waste materials such as bones, but is now only used in exceptional cases.

- Casein glue, which consists of casein, a milk protein, and is produced in combination with calcium hydroxide, i.e., slaked lime

Compared to glutin glue, casein glue has the advantage of heat resistance. It is also water-resistant. However, it is rarely used by do-it-yourselfers, but rather by carpenters.

The wood glues mentioned here are not only environmentally friendly because they are made of natural materials, but some of them are also food-safe. However, the selection of natural glues is small and they are more suitable for professional crafts than for home use. Therefore, they are also not available in every market.

Wood glues with synthetic ingredients, on the other hand, are usually dispersion adhesives that are free of solvents as well as formaldehyde. However, formaldehyde glues are also available, as well as polyurethane glues and epoxy resin adhesives. White glue is one of the best known synthetic wood glues.

Synthetic wood glues thus have several advantages. For example, they offer a wide portfolio of possibilities and securely bond many different materials together. They can also withstand high loads, although, of course, attention should be paid to the classification from D1 to D4. In addition, a wide variety of these wood glues is available on the market.

A major disadvantage is the that of the chemical ingredients, some of which can also be responsible for the strong odor as well as potential adverse health effects. Safety equipment should therefore always be worn when working with synthetic adhesives.

PVA Wood Glue (White Glue)

The name white glue says it all, because before the curing phase it has a milky white color; however, it cures transparently. This results in a highly inconspicuous glue line. White glue does not need to be thinned or specially mixed, although it can be mixed with crosslinkers or curing agents. Caution is advised with hardwoods as well as tropical woods, as these often contain a lot of resin and/or oil. These substances can impair the bonding performance of the white glue.

PROS

- Formaldehyde-free and therefore odorless

- Cures transparently, making it inconspicuous

- Fast curing at room temperature

- Glue for wood forms a strong bond

CONS

- Most are not food-safe

- Some types of PVA wood glue are not waterproof

- Not suitable for tropical woods or hardwoods

Recommendation: ELMER’S Carpenter’s Wood Glue

Elmer’s PVA wood glue boasts a bond that is stronger than wood itself. This white glue is non-toxic and produces no harmful fumes. It is also easy to clean up with some water. This is one of the strongest wood glue options, as it is resistant to heat, water, mold, and mildew, and can be used both outside and inside. You can also paint, stain, and sand the adhesive once it has cured.

- Bonds stronger than wood

- Non-toxic, no harmful fumes, and easy to clean

- Resists heat, mold, and mildew

With an average curing time of at least 24 hrs, you may have to wait a little while for this wood glue to cure fully. The nozzle can also be prone to leftover dried glue clogging it up. Other than these minor disadvantages, you would be remiss to pass up on using this effective wood glue, which claims that the wood will break before the bond does.

Polyurethane Glue for Wood

The most modern version of the best glue for wood today is polyurethane glue. This glues most materials together safely and permanently. This means that joining different materials is also no problem. Of course, this also applies if you want to glue wood.

Polyurethane glues are not only highly water-resistant, but also free of solvents. If you want to bond wood outdoors, polyurethane glue should definitely be on the shortlist of adhesives, because this adhesive is perfect for difficult or unstable weather conditions on account of it being a weatherproof wood glue.

Polyurethane glue for wood is available in both one- and two-component formulations. Both cure elastically and flexibly and are therefore suitable for bonding different materials, even if they have different coefficients of thermal expansion or are exposed to high vibrations.

One difference is that the one-component glue takes up to three days to fully cure, while the two-component adhesive has a limited pot life and only needs about twenty-four hours to cure fully.

PROS

- Available as both one- and two-component adhesives with different bonding properties

- Highly resistant to environmental and weather conditions

- Resistant to aging

- Achieves optimum structural strength, allowing the adhesive seam to withstand high loads

- Gap-bridging capacity is very high

- Adhesives of choice for bonding large surfaces

- Processing possibilities are as varied as the materials compatible with them

- Weatherproof wood glue that is suitable for outdoor use

CONS

- More suitable for fast and experienced craftsmen due to the short pot life

- More likely to be in the high-price range

Recommendation: LOCTITE Premium Polyurethane Construction Adhesive

This is a polyurethane-based adhesive for wood that is easy and save to use on both indoor and outdoor projects. The Loctite brand guarantees that your adhesive is likely to last equally as long as the surface to which it has been applied. In fact, this adhesive is up to eight times stronger than most other construction-grade adhesives on the market. Loctite’s waterproof wood glue is also paintable and will cure in even the coldest of temperatures. Being VOC-compliant as well, this is the ideal choice for adhering your wooden surfaces.

- Safe to use, repositionable and VOC compliant

- Constructed of 100% polyurethane

- 8 times stronger than your typical construction adhesive

This product is highly versatile, and can be used on a number of surfaces. However, this adhesive is not ideal for non-porous surfaces.

Epoxy Wood Glue

If you want to glue wood, epoxy wood glue could also be a good choice, because it forms a highly durable and resilient bond. These adhesives consist of two components, namely the resin and a hardener. Thus, epoxy adhesives belong to the so-called reaction adhesives category, as they cure through a chemical reaction. Epoxy adhesives are highly resistant to mechanical as well as chemical influences. Epoxy is an example of a waterproof wood glue. It can be used not only as wood adhesives, but also as a gap filler.

PROS

- Becomes very strong, forming a durable and highly resilient bond

- Resistant to most mechanical influences as well as oils and aggressive substances

- Solvent-free

- Bonds a wide range of materials, including wood, glass, concrete, various plastics, and ceramics

- Filler materials can be added (such as color pigments, inhibitors, or accelerators)

- Pot life is indicated so that the user knows exactly how much time is left for bonding

CONS

- Quite expensive

- Not supplied in a double-chamber cartridge, meaning you have to mix the components yourself

- Mixing is not particularly easy, because the mixing ratio must be absolutely exact

- Epoxy gives off potentially harmful fumes before curing, so you have to wear protective clothing and equipment

Recommendation: GORILLA Two-Part Epoxy Syringe

Gorilla’s two-part epoxy wood glue is durable, lasting, and gap-filling. It can be used on a multitude of surfaces that require a stong and durable bond. This adhesive sets quickly and dries clear, and is easy to use as a result of its syringe-like packaging. The product includes two separate barrels containing a resin and a hardener, as keeping these separate will prevent any chemical reactions and subsequent hardening from taking place.

To begin, you must dispense equal amounts from each tube and mix the components together thoroughly for some time. You will then have five minutes during which you can apply the epoxy wood glue, after which time it will begin to harden. You must then allow the epoxy to cure for a minimum of 24 hours to ensure a tough and lasting bond.

- Strong, permanent, fast, and gap-filling epoxy glue

- Cures quickly, dries, clear, and is great for multi-surface application

- For tough repairs requiring a durable bond and solvent resistance

It can be difficult to achieve the proper mixing ratio, as the two barrels dispense the liquids at different rates.

Superglue

Cyanoacrylate adhesives, also known as instant adhesives, are perfect for small and selective bonding. However, their very short curing phase prevents them from working over large areas. A good superglue should also be used for bonding where fixing is impossible.

PROS

- Firm and permanent connections are possible

- Perfectly suitable for quick work

- Suitable for many different materials

- Different dispensing tips are available

- Varied consistencies of the superglues available on the market

CONS

- Skin contact should be avoided at all costs due to the short curing phase

- Unsuitable for large-area bonding due to the short pot life

Recommendation: GLUE MASTERS Professional-Grade Cyanoacrylate Superglue

This premium-grade superglue offers one of the strongest wood glue alternatives, as it cures almost immediately and has a long shelf life, as the nozzle will not ever clog or jam. You need only a small amount of this medium-bodied glue in order to achieve a strong bond that will cure within just 15 seconds. The nozzle allows for precision and an even flow, making it ideal for detailed projects. You can use this glue on a number of different surfaces, although it cannot be used on any fabrics or clothing.

- Premium industrial-strength Cyanoacrylate

- Quick and easy to use with an extended shelf life

- Highly versatile

This superglue is toxic to work with, so it is important to work in a well-ventilated space. The viscosity has also been said to be a little too thin. However, this product makes up for these deficits with its high quality and efficacy.

Gluing Wood to Other Materials

While you can use glue to bond wood to wood, you can also use this glue to bond wood to other surface materials, such as glass, concrete, metal, and tile. When bonding wood to another material, you will need to take the properties of both the wood and the other substrate into account when selecing the strongest wood glue.

Gluing Glass to Wood

When bonding glass to wood, there is a fundamental problem: While wood is a working material with many pores, glass is a particularly smooth and immobile material. Glass does not work like wood, so stresses can occur between the two materials after bonding. Therefore, choosing the right adhesive for gluing glass to wood is enormously important.

Bonding clear glass in particular is difficult, as even transparent adhesives can leave streaks on it. With coated glass, on the other hand, it is possible in individual cases for the coating to detach, which must also be taken into account. The adhesive should therefore always be tested on an inconspicuous area before it is used to bond larger surfaces or conspicuous areas.

Mounting adhesive is suitable as an adhesive, but not in the case of clear glass for the reasons mentioned above. A transparent adhesive is suitable for this, which at best is still flexible after the curing process to compensate for expansion as well as contraction of the wood. A two-component adhesive could also be the means of choice for bonding glass to wood.

Gluing Wood to Concrete

Especially for a passionate do-it-yourselfer, many a situation arises in which you want to glue wood to concrete. This is easily possible with the right know-how. A solid assembly adhesive is suitable for use as an adhesive.

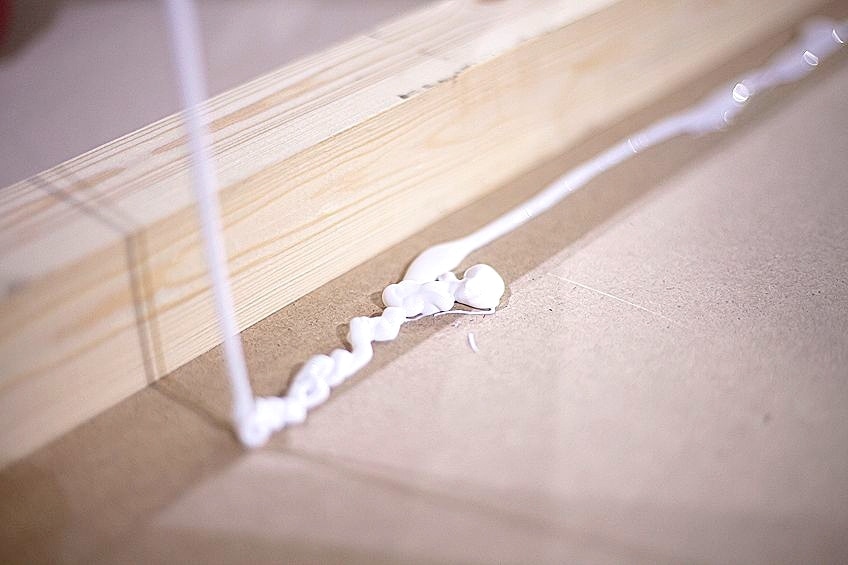

This should be applied in the shape of a bead and in wavy lines so that it spreads optimally and there are not too many air pockets that could impair the bonding result. Furthermore, the adhesive should not be applied too thinly to compensate for odd spots and cracks.

Glue for Wood and Metal Bonding

Gluing wood to metal is certainly possible, but doing so requires not only the right adhesive, but also careful work. Metal has a much greater internal strength than any type of wood, so bonding with an unsuitable adhesive can cause the top layer of wood to crack.

It is advisable to use a two-component epoxy resin adhesive or an acrylic adhesive. However, it must also be remembered that there are many different metals that have different properties. Not every one can be bonded equally well with wood.

Gluing Tiles to Wood

As already mentioned, wood “works” – that is, it contracts or expands, depending on the temperature and humidity. This means that gluing tiles directly to wood is not a good idea, because the tiles can poorly compensate for the movements of the wooden substrate. The result is tension, which can ultimately even lead to cracks in the tiles. The remedy here is decoupling mats. These are usually glued to the wooden substrate. The tiles are then laid on this with the help of tile adhesive.

How to Use Glue for Wood

Gluing wood is not a job that can be done only by professionals. Nevertheless, some things must be taken into account, especially when you are a beginner at using glue for wood. We tell you in our wood gluing step-by-step instructions how best to proceed.

Preparatory Work

Before the actual bonding, you need to tackle the preparation of the substrate, which is essential for the durability of the adhesive seam. The substrates must therefore be thoroughly cleaned of rust, grease, and all dirt deposits.

Furthermore, the substrate should be completely flat. You can achieve this by planing, sanding, or grinding. In this way, you can also easily remove old paint from wood. Note that after such work, the substrate must be cleaned again from any sanding dust.

After that, the surface can be primed using diluted wood glue. It is essential to prime absorbent surfaces so that the wood glue is not completely absorbed.

For priming, dilute the glue and apply it to the adhesive surfaces of the substrates. Once this has dried completely, you can start the gluing process.

The Gluing Process

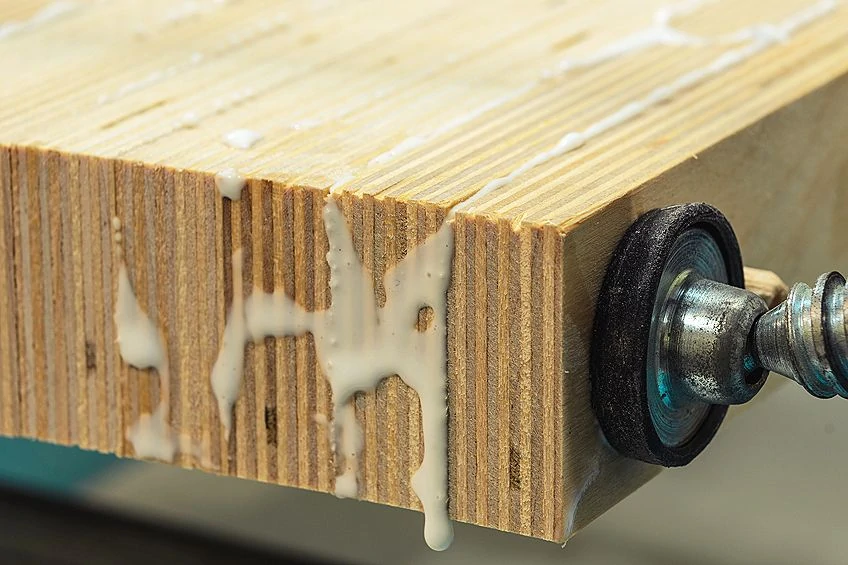

The substrates are now coated with wood glue on both sides. Be generous, but do not apply so much to the surfaces that it all oozes out. Join the substrates together and move them back and forth very lightly and carefully to dissolve any trapped air bubbles. Then fix them in place. Excess glue must be immediately absorbed with a wooden spatula and any remnants can then be wiped with a damp cloth.

Curing and Loading of the Joints

There is no general answer as to how long the wood glue needs to cure completely. Take the drying time from the manufacturer’s data sheet into consideration, although it is always better to leave it for a bit longer so as to ensure that it has cured properly. Until final curing, leave the glued substrates fixed in place.

How to Remove Glue From Wood

To remove glue from wood, you need to decide between treated and untreated wood. If the wood was previously treated or painted, proceed as follows:

- Heat the adhesive carefully and slowly using a hair dryer, but be careful not to damage the paint. A low setting of the hair dryer should be sufficient. Aim the hair dryer at the adhesive for a few minutes at a distance of 20 cm.

- From time to time, check to see if the heating is finished. You should be able to pick up the wood glue with a paper towel. If the glue is still tougher than before, heat it for some time at a higher level until it can be removed.

- Another way to remove wood glue is to scrape it off with a stove scraper. However, you should be careful not to damage the varnish.

Glue is easier to remove from untreated wood than from treated wood. Proceed as follows:

- Sprinkle a lint-free cloth generously with acetone-free nail polish remover and rub it over the wood glue until it comes off.

- Sanding is also a good option that can be implemented. For this, you can choose sandpaper, some steel wool, or a steel sponge. Take care not to damage valuable wood.

Frequently Asked Questions

How Long-Lasting Is the Best Glue for Wood?

Wood glue is probably one of the most durable adhesives of all. If properly stored in tightly closed containers and protected from heat and direct sunlight, it can even last for several decades.

What Sticks to Wood?

In principle, wood can be bonded to all conceivable materials. However, a suitable adhesive should be used and the different material properties such as porosity and coefficient of thermal expansion must be taken into account.

What Is the Best Glue for Wood and Metal?

If you want to bond wood and metal, you should use a two-component epoxy resin adhesive or a polyurethane adhesive. The adhesive must be able to compensate for the different internal strengths.

What Is the Best Glue for Wood and Stone?

If you want to bond stone to wood, you should use a solid polyurethane adhesive or a high-quality assembly adhesive. Pay attention, especially with natural stone, to the gap-bridging properties of the adhesive.

Bonding wood to other materials is not as easy as you might think. The different material properties in particular can throw a spanner in the works of many a craftsman if the wrong wood adhesive is used. We hope we have been able to help you with our wood adhesive guide.