Types of Varnish – Wood Coating Finishes and Their Uses

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Regardless of what type of woodcraft you’re into, there are loads of products to choose from when it comes time to finish your workpiece. Previously, paint was the only good option if you wanted a good-looking finish that would last the lifetime of your workpiece, but these days there are loads of wood treatment oils and solvents to choose from. Even though oils like tung and linseed oil have become increasingly popular over the years, one of the go-to solutions for a long-lasting (and good-looking) wood treatment has been varnish. This being said, let’s have a look at exactly what varnish is, the different types of varnish available to you, and how to use varnish effectively on your wooden workpiece.

Table of Contents

What Is Varnish?

There is a seemingly endless variety of varnishes for you to choose from, but have you ever wondered what exactly varnish is? Varnish can be characterized as a wood treatment that is applied in the form of a liquid to the surface of a wooden workpiece. Once applied varnish seeps into the wood’s fibers altering its appearance and sealing its pores.

Varnish tends to leave a film-like coat on the surface of wood which allows it to repel things like moisture and dust with relative ease. It also reduces the amount of maintenance needed for the surface of any wooden workpiece by protecting it from things like impact, abrasion, food stains, and the effects of direct sunlight.

The word varnish is actually derived from the Latin word for a type of resin which was in turn derived from the Greek word for amber, reflecting the use of various types of tree extracts to make the stuff to protect wood with. The practice of varnishing wood is originally from ancient Egypt where resin was not only used to prolong the life of wooden workpieces and beautify them, but was also used in mummification.

The mummy of Tutankhamun was famously covered in a resin that had been applied while still too hot, fueling the suspicion that his burial was done in haste.

The earliest version of varnish actually didn’t differ all that much from the varnish types used today, albeit that they were made with substances that were around at the time. Originally, varnish was made of natural resin, tree sap, and a solvent that could then be applied to a brush and/or cloth and slathered onto the surface of your workpiece. Now varnishes may contain a mixture of natural and synthetic resins.

There are other varnish types developed all over the world too, and they weren’t just used to preserve wood either. In parts of ancient Asia, there were numerous complex formulas for different varnish types which could be used for all manner of applications.

These applications include but aren’t limited to the preservation of silk, the repelling of water, the polishing of precious metals, and even weapon maintenance.

Varnish is pretty versatile but it’s also one of the most hazardous wood treatment substances out there. What makes varnish so dangerous you ask? Well, considering that it consists of various solvents and binders it tends to be pretty flammable. Therefore, when working with varnish you should always ensure that you have adequate ventilation and ensure that anything you use to apply it is disposed of adequately.

Types of Varnish

There are many types of varnish for you to choose from, all of which have their own unique characteristics that make them suited for their intended application. Even though they’re all classified as varnish they all require their own respective means of application to work as intended. This being said, we’ve created a short rundown of all of the varnish types you could come across, some of the pros and cons associated with them, and what their intended applications are.

| Type of Varnish | Characteristics |

| Spirit Varnish |

|

| Acrylic Varnish |

|

| Exterior Varnish |

|

| Polyurethane Varnish |

|

| Yacht Varnish |

|

| Oil Varnish |

|

| Alkyd Varnish |

|

| Lacquer Varnish |

|

Spirit-Based Varnish

If you’ve ever heard the term “French polish” used in furniture making, this is the type of wood treatment they’re referring to. Spirit-based varnish has been used for a long time and has proven to be an effective means of both beautifying and protecting various wooden workpieces throughout history. Even though it is one of the most well-known varnish types out there it isn’t always considered a varnish.

Unlike most other types of varnish, which are made of synthetic materials, spirit-based varnishes are made from the secretions of a certain species of beetle found in Eastern Asia. These secretions are typically found in the form of flakes that are diluted in alcohol and have their consistencies improved before they’re used on wood.

Spirit varnish is also commonly referred to as shellac, but there’s a key difference between what most people would refer to as shellac and actual spirit varnish. While shellac tends to have a waxy consistency to it, spirit varnish tends to have a thinner consistency which is what causes it to run when it is overapplied. Spirit varnish can actually be used to prime certain surfaces for other types of varnish or paint too. It is particularly favored by makers of musical instruments like violins.

If you’re wondering what type of finish you’ll be getting if you choose to use spirit varnish as your weapon of choice, it produces a clear thin surface layer that doesn’t obscure the grain and texture of your workpiece. However, this thin layer does not hold up to external forces and therefore should not be used on any workpiece that will be spending prolonged periods of time outdoors or exposed to direct sunlight.

- Provides protective layer

- Versatile

- Improves aesthetic impact of wood workpieces

- Can be used to prepare surfaces for other varnishes and paints

- Base consists of natural materials

- Provides a clear finish and maintains the texture of wood

- Cannot be used outdoors

- Does not provide protection against impact and abrasion

- Cracks easily

- Does not protect against UV light

Acrylic-Based Varnish

One of the primary concerns when applying varnish is the presence of VOCs (volatile organic compounds) in their makeup. These chemicals can cause serious discomfort when inhaled so it’s always advised to open and apply to your workpiece while outdoors. Acrylic varnish on the other hand contains little to no VOCs and therefore can be applied both indoors and outdoors, which is pretty cool.

This is all thanks to its water base, which not only makes it significantly safer to work with, but it also ensures that the varnish dries quicker, which is great if you’re in the middle of a time-sensitive project. Its acrylic makeup also creates a barrier that protects your workpiece against the effects of UV light, ensuring that your finish will not fade over time.

While we’re on the topic of finishes, acrylic-based varnish has a clear finish that sits tightly against the surface of your workpiece. This finish is virtually transparent which ensures that the texture and grain of your wood are still accessible, although there are variations of an acrylic varnish that offer a lighter or darker tone for your wood if that is what you’re looking for.

When it comes to acrylic-based varnish there are two points that are brought up most often. The first is that since acrylic varnish is water-based, it is significantly easier to clean up in case of a spill. The second is that acrylic varnish does not spread and penetrate into wood uniformly, which can lead to patchy spots on the surface of your workpiece if it is not managed correctly.

- Contains little to no VOCs

- Water-based formula

- Easy to clean up if spilled

- Readily available

- Relatively inexpensive

- Can be applied indoors and outdoors

- Dries quickly

- UV-resistant

- Available in multiple finishes

- Does not absorb into wood well, resulting in patchy areas

- Can be challenging to apply to denser wood species

- Color isn’t always as effective as its oil-based counterparts

Exterior Varnish

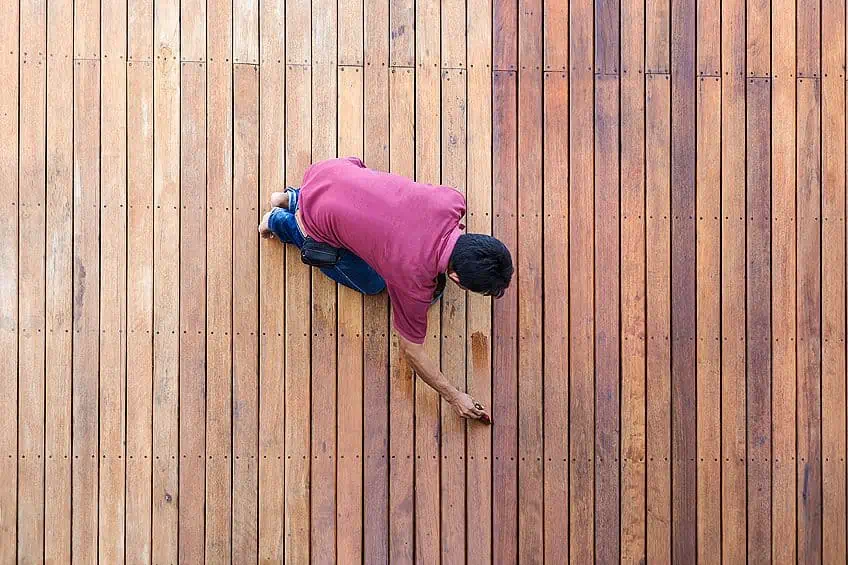

This is a great clear varnish for wood. If the name of this varnish isn’t a dead giveaway, exterior varnish has been designed and produced to be used outdoors. As you’d expect, this type of varnish is exceptionally durable and can be used on all manner of outdoor wooden workpieces. Not only does it do a great job of protecting wood workpieces outdoors, but it does a pretty decent job of improving their looks too.

If you live in a state that has unpredictable weather patterns but still want to option of lounging outdoors on a deck, then this might be the type of varnish you’re looking for, especially if you’d rather not use paint. Not only is this type of varnish UV resistant, but it also repels rain and other forms of moisture, preventing rot and splitting over time.

Usually, when a substance has the ability to repel moisture like this (a characteristic called hydrophilic) it means that it completely seals the wood. Exterior varnish is different-though, as it still allows the wood to “breathe”, ensuring that your wooden workpieces don’t become brittle over time thanks to oxygen deprivation.

If you still aren’t impressed by this type of varnish, you should consider the fact that it’s also been designed to deter the effects of fungi. Fungicides have been added to the makeup of exterior varnish to ensure that they are capable of repelling most forms of fungus and other invasive species like termites and grubs. Sounds great, right? Well, if you’re going to be using this type of varnish it’s best to plan well in advance as it can take a while to dry completely.

- Graded for exterior use

- Highly durable and flexible formula

- Capable of lightening or darkening wood

- Provides a thick layer of protection

- UV-resistant

- Resistant to all forms of moisture damage

- Repels both insects and fungi

- Allows the wood to breathe

- Contains VOCs

- Takes a long time to cure and dry

- Obscures the texture and grain of the wood

Polyurethane-Based Varnish

Polyurethane-based varnish has pretty much all of the characteristics you’d expect from anything coated in this thermoplastic. Polyurethane (PU) varnish is one of the most robust types of varnish out there, featuring a coating that is hard-wearing and extremely durable regardless of the application.

It should come as no surprise then that this type of varnish is used almost exclusively on surfaces in high traffic areas.

This means that you can find it in long wooden entryways, the wooden floors in office buildings and atriums, or on wooden countertops that are frequently used. What makes polyurethane so durable though? Well, polyurethane does a great job of soaking up friction and the subsequent heat produced by it, which allows it to dissipate forces that would otherwise damage a wooden surface with ease.

Polyurethane-based varnish can be thought of as one of the many types of exterior varnish available today, thanks to its incredible durability and versatility. At its core, PU varnish is essentially like any other polyurethane coating, which means it doesn’t so much seep into the pores of the wood, but rather forms an external protective layer much the same way that paint does.

However, due to the fact that it doesn’t bond with wood fibers the same way that conventional varnish does, it means that a primer is often needed to ensure that it has enough surface friction to adhere correctly. Once applied and dried, PU varnish provides either a matt, satin or gloss finish depending on the type you’ve purchased.

One of the key selling points of PU varnish is the fact that it is incredibly robust, even when compared to exterior varnish. It is highly resistant to acidic substances, impact, abrasion, moisture, and heat. One noticeable drawback of this varnish type is that it does not have any UV resistance, but if a large enough volume is applied it should do a reasonably good job of mitigating the effects of direct sunlight.

- Extremely robust

- Versatile

- Easy to use

- Great for high traffic areas

- Resistant to acids, impact, abrasion, moisture, and heat

- Available in satin, matte, and gloss finishes

- Requires primer to be applied effectively

- Does not bond with wood fibers

- Is not resistant to UV light

- Obscures the texture of wood

Yacht Varnish

This is another great clear varnish for wood. Like exterior varnish, yacht varnish pretty much speaks for itself. This type of varnish has been designed specifically for use with seafaring vessels, in the hope that it would allow wooden surfaces to last significantly longer in the face of seawater, strong winds, and buffeting from sand particles while out on the open ocean.

Back in the day, yacht varnish was referred to as “spar varnish” as it was typically used to ensure that the spars on a sailboat wouldn’t be affected by water. If you’re not sure what the spar of a boat is, it is the long, thick poles on which the sails are hoisted. As you can imagine then, the varnish needed to protect these huge wooden pieces needs to be extremely durable, and yacht varnish is definitely up to the challenge.

Originally, yacht varnish was designed to be purely functional, and not much attention was paid to the color or texture that it would produce once applied to the spars or hull. These days, yacht varnish tends to have a sheen finish that not only makes your boat look good but is capable of flexing with the spars and/or hull as they bend underneath the immense strength of the wind and ocean.

Even if you’ve never spent time out on the open ocean, you probably know that spending a day at the beach can leave you with some really bad sunburn if you aren’t careful. Too much sunlight is bad for wood too, which is why yacht varnish is UV-resistant too! Unless your wood is going to be exposed to large quantities of water, we wouldn’t recommend using yacht varnish for any other application though, as it can be expensive and if we’re being honest, overkill for everyday applications.

- Highly durable

- Resistant to impact, abrasion, and extreme cold

- Great rigidity to flexibility ratio

- UV-resistant

- Repels various forms of moisture

- Provides a smooth gloss finish

- Ideal for water-borne vessels

- Expensive

- Should not be used for other applications

- Contains VOCs

Oil-Based Varnish

If you’re involved in woodworking, then you’ve probably used or at the very least heard of drying oils. These are often naturally occurring oils that were originally discovered and used in Asia thanks to their ability to both beautify and protect wood workpieces. These oils also provide a degree of water resistance to wooden surfaces, and as a result, saw them used on small finish boats in the region at the time.

These oils technically aren’t varnish, as pure drying oils don’t contain any solvents. They are considered by many to be wood treatment oils instead, as they improve or change the look of wooden workpieces while providing a decidedly mild layer of protection against moisture, insects, and impact to the wood’s surface.

They’re called drying oils due to the fact that when examples of these substances with solvents are applied to a wooden surface, the solvent evaporates/dissolves, leaving only the oil behind, which then seeps into the wood’s pores and bonds with its fibers. Some of the most common examples of these types of “varnish” are tung oil and linseed oil.

Drying oils are more of a traditional way to treat wooden surfaces compared to modern varnishes. They are nowhere near as durable as modern varnishes though, and require frequent maintenance and reapplication, especially if they’re 100% pure. However, they allow you to preserve the natural texture and tone of your wooden workpieces while being relatively easy to maintain, the same which cannot be said for the vast majority of their modern synthetic counterparts.

- Versatile

- Easy to use

- Pure examples contain no VOCs

- Water-resistant

- Improves and maintains wood color

- Does not obscure wood’s texture

- Relatively inexpensive

- Various colors available

- Not as durable as modern varnishes

- Some examples contain solvents that contain VOCs

- Requires frequent maintenance and reapplication

- Not suitable for exterior furnishings

- Long drying and cure times if pure

Alkyd-Based Varnish

It can be pretty challenging to define what an alkyd-based varnish is compared to some of the others we have covered previously. This is because alkyd can be added to pretty much any varnish solution to improve its durability, drying time, and aesthetic effect on wood. Alkyd-based varnishes provide a clear finish to wooden workpieces that do not obscure the wood’s texture and grain.

One of the key reasons that alkyd is either added to existing resins or used to create a resin is that it has a high resistance to the effects of UV light and temperature variation, which are key characteristics for any varnish that will be used to treat exterior wooden furnishings. It also happens to resist condensation and water pretty well too, making it a sure-fire option for wooden decks.

Besides providing a good layer of protection for exterior furnishings, alkyd varnish also has the ability to improve the color of the wood you’ve chosen to use it on. This is thanks to the presence of vegetable oils in its makeup, which can lighten, darken, or intensify the overall tone of the wood it’s applied to, which is great.

Previously, we mentioned that it can be pretty difficult to define what an alkyd varnish is since alkyd can be found in most types of oil-based varnish. This ensures that they dry quickly, improve color, and are slightly more durable. Alkyd can be combined with resins to treat a number of materials, which makes it one of the most versatile surface treatment substances out there.

- Easy to use

- Versatile

- Protects against moisture

- UV-resistant

- Improves resistance to impact and abrasion

- Dries and cures quickly

- Can be added to other varnishes

- Improves color of wood

- Contains VOCs

- Does not significantly improve impact and abrasion resistance

Lacquer

If you’re a wood treatment purest, then you probably already know that lacquer is not considered to be a varnish. However, it is functionally the same in that it is typically used to improve the look and protect the surface of wooden workpieces. Varnish is essential shellac that has been diluted in alcohol, and is characterized by being a hard, shiny surface coating for wood.

Lacquer provides a quick and simple way for you to improve the look of a wooden surface while providing a slick and hard outer layer of protection. The cool thing about lacquer is that unlike conventional varnish it can be applied using a brush/roller or you could purchase an aerosolized version and simply spray it on the surface in question.

Not only is lacquer relatively cheap and easy to apply, but if you end up overapplying it or decide that you’d rather go with another wood treatment, it’s easy to remove too. All that you need is some acetone or lacquer thinner on a clean cloth and you can remove the finish in just a few minutes! It does contain VOCs though, so you shouldn’t apply it indoors.

- Easy to use

- Provides strong surface coating

- Can be used on solid wood and engineered wood

- Available container or aerosolized forms

- Easy to remove

- Cures and dries quickly

- Resistant to all forms of moisture

- Mold-, impact-, and abrasion-resistant

- Does not obscure grain or texture of wood

- The surface layer can be brittle

- Contains VOCs

- Not as durable as other wood treatments

How to Apply Varnish to Wood

What is varnishing? Put simply, varnishing wood means applying a varnish to the surface of a wooden workpiece. This is done to improve the aesthetic impact of your workpiece and provide a layer of protection against things like moisture, insects, impact, abrasion, heat, cold, UV damage, and/or splitting. Varnish is exceedingly easy to use, and depending on the type of varnish you’re using can require little to no maintenance throughout the lifetime of the workpiece in question.

Prepare Your Surface

Like painting a wooden workpiece, you should prepare your surface adequately. This means cleaning the wood with some soap and water and allowing it to dry completely. Next, fill any holes or chips in the wood’s surface with some wood filler and allow it to cure and dry for the manufactures recommended time period.

Next, you can sand the surface of your workpiece, but most modern products will function effectively without any sanding needed. Ensure your workpiece’s surface is free of any foreign particles before continuing to the next step.

Prime Your surface

While you can use a number of varnish primers out there, if you’re on a budget or pressed for time you can use a thin coat of varnish on the surface of your workpiece to create a base for the main coat. All that you need to do is get a small amount of varnish on a brush and apply it to the surface of your workpiece, and ensure you follow the length and grain of the wood.

Once applied, allow it to cure and dry for the manufacturer’s recommended time period before moving on to the next step in the process. Finally, give your initial coat a light sanding with some fine grit sandpaper and clear any dust or varnish particles from the surface of your workpiece using some compressed air and/or a clean cloth.

Apply Your Varnish

Now apply your second and final coat. Get some varnish on your brush or roller and begin applying it to the surface of your workpiece. While you applied the first coat by following the length and grain direction of the board, this coat will be applied perpendicular to the direction you initially went with. Be sure to take your time to avoid under or overapplying in certain areas.

Once this coat has been applied, allow the varnish to dry completely for the manufacturer’s recommended time period. If you aren’t quite happy with the color or thickness, simply apply another coat, but ensure that you apply it perpendicular to the one you just applied to create a crisscross effect, which will improve the durability of your finish.

Now that you know what varnish is, why it is used, and the different types of varnish that are out there it’s time for you to get out there and put your newfound knowledge to the test. Remember to always ensure that your workspace is well-ventilated when working with any type of varnish and that you are always wearing a set of gloves and a facemask.

Frequently Asked Questions

What Is Varnishing?

The act of varnishing can be characterized as applying varnish or a related product to a wooden workpiece. This is done to improve the aesthetic impact of said workpiece, and/or provide a layer of protection against external forces.

Are There Different Varnish Colors for Wood?

Are there different varnish colors for wood? Yes, there are many varnish colors available for a wide variety of wood types. These can be used to lighten, darken, or simply intensify the natural hue of a wooden workpiece.

How Long Does Varnish Last?

This is a tricky question to answer as it largely depends on the type of varnish being referred to. Oil-based and exterior varnishes can last well over a year, but varnishes that are less durable like alkyd and water-based varnishes can be less durable and therefore require more maintenance over long periods of time.