Polyethylene and Polypropylene Glue – How to Bond Thermoplastics

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Plastics play a huge part in our day-to-day lives; they help us build, maintain, and protect ourselves and our belongings. How much do you actually know about plastics though? There are several types of plastic available for commercial and private use, but some of the most commonly used types of plastic are polyethylene and polypropylene. These plastics are easy to work with, extremely versatile, durable, and readily available, so let’s have a look into how to use these plastics, what exactly they are, and what the best way to bind them together really is.

Table of Contents

What Is Polyethylene?

Polyethylene is one of the most used materials on the face of the planet, it ensures that we have lots of the comforts and conveniences we enjoy in modern life, but what is it? At its core, Polyethylene is the name given to a group of materials, each of which has been designed to fulfill certain roles in industry, but at their core, they are essentially the same material.

Polyethylene traces its roots all the way back to the early 1930s where it was used primarily as a coating for things that needed a bit more durability, or characteristics like slickness, ease of maintenance, or resistance to things like abrasion, impact, and chemical damage.

From then on it was used in mass production during the second world war industrial effort, putting itself and the allied forces on the bleeding edge of lightweight durable materials. Once the war was over it was used as a catalyst for adhesives, coatings, bushings, foams, and many other instances where it served as an affordable replacement for conventional materials of the era.

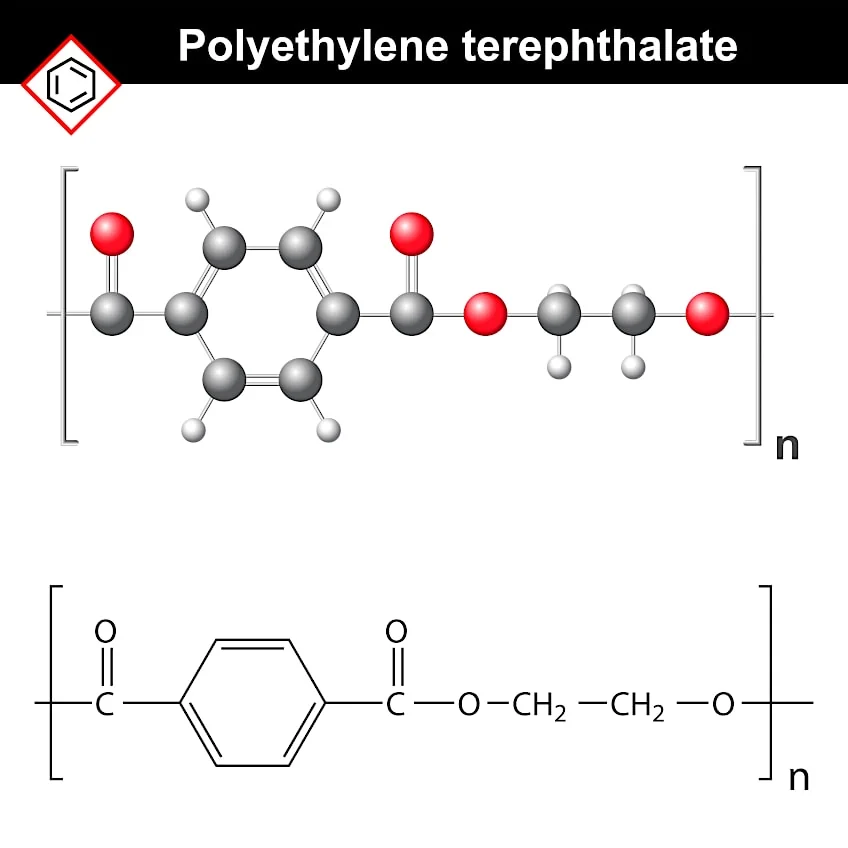

These days we can find Polyethylene in our smartphones, cars, bikes, skateboards, molds, piping, and even art. Polyethylene is made by fusing TDI and MDI polyols, which are organic compounds made up of lots of different molecules that have a strong bond with one another. This is what gives Polyethylene (also known as PE) its rigidity and tensile strength.

Polyethylene is often combined with things like monomers and elastomers when used in the engineering industry to add and remove certain characteristics when being formulated for a certain application.

What Is Polyethylene Used For?

- Insulating refrigerator units

- Insulating homes

- Furniture stuffing

- Bed mattresses

- Engine mountings for automobiles

- Coatings

- Adhesive materials

- Clothing

What Are the Advantages and Disadvantages of Polyethylene?

- Good at low temperatures

- Easy to work with

- Abrasion and impact resistant

- Can be used to cast or coat

- Affordable

- Performs poorly in very high temperatures

- Not particularly weather-resistant

- Solvents can degrade coatings and castings

- Utilizes volatile organic chemicals in production

- Not biodegradable (but is recyclable)

What Is Polypropylene?

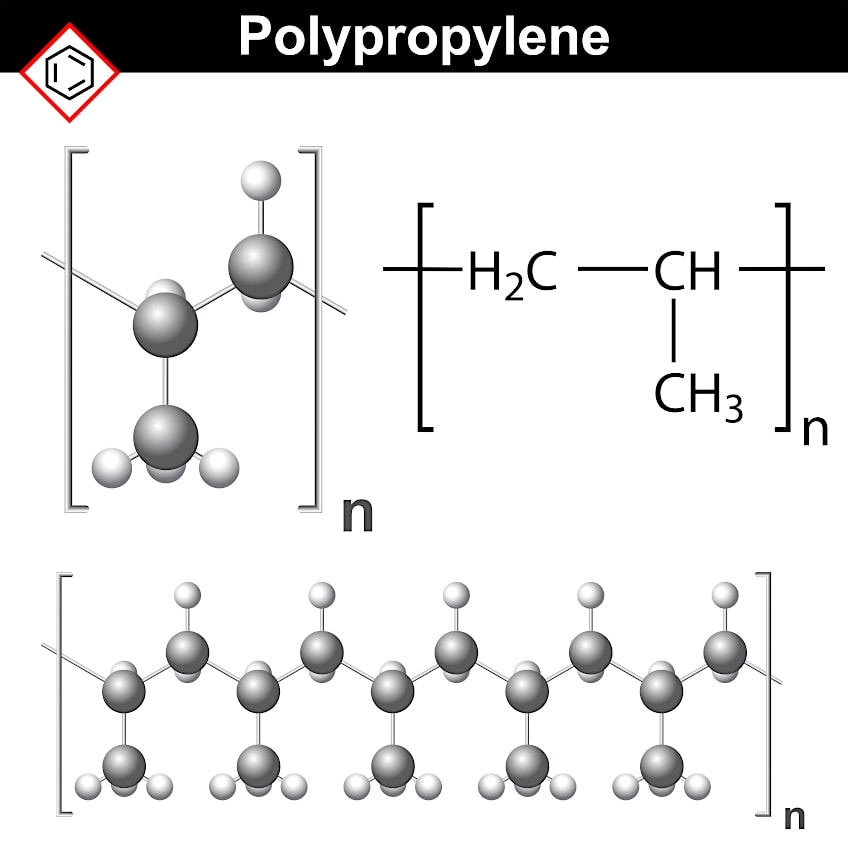

Like Polyethylene, this is an equally durable and versatile material that is used all over the world in various industries to create literally thousands of products that improve our everyday lives. But what is polypropylene? Well, it’s a lot like Polyethylene in the way that it’s derived from monomers instead of polyols like polyurethane is.

Polypropylene was first synthesized in the early 1950s a full 20 years after Polyethylene was introduced into mainstream production practices. Although thanks to all the research and applications Polyethylene had been used up to this point, polypropylene was pushed into mainstream industries only a year after it was first synthesized.

At the moment, it’s theorized that the world uses more than 45 million tons of the stuff in various industries such as automotive manufacturing, tools, plumbing, packaging, food production machinery, appliances, electrical equipment, and even structural reinforcement in small quantities.

What really sets polypropylene apart from its sibling Polyethylene is that it has very low surface friction, so much so that it’s nearly sheer in texture which makes it pretty slippery. This makes it an ideal candidate for replacing certain plastics, gears, top surfaces, and even furniture.

Although it has a similar tensile strength to Polyethylene, polypropylene is noticeably less dense which makes it ideal for applications where weight needs to be saved. One of the most common ways these characteristics are exploited is by using polypropylene to create what is known as living hinges, or plastics that can be bent repeatedly in either direction without breaking.

The elasticity of materials can be increased by simply adding polypropylene to their chemical composition. An added benefit of such an addition includes increased chemical resistance and insulation. Another noticeable trait of polypropylene is its ability to be melted down and remolded without significantly degrading on a molecular level.

What Is Polypropylene Used For?

- Living joints

- Insulation

- Packaging

- Plastic gears and mechanisms

- Slippery surfaces

- Appliances

- Tools

- Additive for other materials

What Are the Advantages and Disadvantages of Polypropylene?

- Readily available

- High elasticity and shape retention

- Low surface friction

- Good chemical resistance

- Good insulation properties

- Doesn’t do well at high temperatures

- Degrades under excessive UV exposure

- Poor resistance to solvent exposure

- Challenging to apply coatings to

- Highly flammable

Can Polyethylene and Polypropylene Be Glued?

Just like you get loads of wood and metal glues, you also get glues formulated specifically for bonding polyethylene and polypropylene together. What would polyethylene and polypropylene glue look like? Well, you would expect this to work like gluing any other plastic, but in reality, it’s actually a bit more complicated than that, because of the unique characteristics of these substances.

Polyethylene adhesion doesn’t work the same way the regular adhesives work on other materials, because most materials simply use an adhesive to act as a joining mechanism or “bridge” between two objects. Polyethylene adhesion involves the fusion of two pieces of polyethylene or polypropylene together on the molecular level, effectively making the two parts one.

The process of not simply binding plastics but fusing them is known as polymerization. This process works much the same way that these substances are made and allows for virtually seamless integration of two pieces of the same different Polyethylene variants. How exactly does polyethylene glue and/or polypropylene glue do this though?

Well, most polyethylene glue and polypropylene glue works with a bonding agent, activator, and heat to catalyze the bonding process, which might sound complicated but in reality, you can have two pieces of the same material bonded within 30 seconds if you’re using a good kit. What does a good glue for polypropylene and polyethylene look like though?

What Is the Best Glue for Polypropylene and Polyethylene?

Finding a good polypropylene adhesive can be challenging, after all, there are loads of companies out there that specialize in the bonding of polymers, all claiming to offer the best polyethylene and polypropylene adhesive products. This is why we have taken it upon ourselves to review some of the top poly adhesive products on the market to make your decision a little easier, so let’s have a look at them!

Best Value: J-B Weld Plastic Bonder Structural Adhesive Syringe

If you’re looking for the perfect tool for bonding polypropylene, you can’t do much better than the plastic bonder structural adhesive from the JB team. This two-part adhesive has everything you’ll need for bonding polypropylene and ensuring that it stays that way for the lifetime of the workpiece.

When it comes to two-part adhesive formulas, most manufacturers typically go with the cheaper option of not providing us with the dual syringe, but not the JB weld team. While it might be convenient and versatile, what makes this polypropylene/ polyethylene adhesive so special though?

Well, besides the resealable dual syringe set up, this plastic weld product can be used for a number of applications, including but not limited to bonding and plastic workpieces. It’s also highly durable which means it can be used on surfaces that are typically exposed to harsh environments such as car bumpers or outdoor furnishings.

It’s not just versatile though, J-B Weld’s two-part adhesive requires little to no preparation to use, simply use the dual syringe set up to apply your plastic joining adhesive in the perfect 1:1 ratio and allow it to set for the manufacturer’s recommended time period. All things considered, its dry and cure times are really fast, being functionally ready in 15 minutes and completely cured in roughly a half-hour. This makes this product perfect for all of those time-sensitive projects.

Bonds created with this product are permanent and can be applied to a variety of thermoplastics but can also be used on things like carbon fiber composites, concrete, tile, and even fiberglass to name just a few. This being said, the JB Weld team provides quite a lot of value for money with their plastic bonder structural adhesive and has proven that you don’t need industrial-grade products to create a strong and reliable bond between poly materials.

- Quick-setting and multipurpose two-part urethane adhesive

- Gap filling system provides a strong and lasting bond

- Takes 15 minutes to set and 30 hours to cure

- Easy to use

- Versatile

- Reusable and resealable

- Works on polypropylene and polyethylene

- Reputable brand

- Dries and cures extremely quickly

- Not a specialized poly adhesive

- Not chemical resistant

- Sold in limited volumes

- Not ideal for beginners

- Only sold in one color

Best Performance: LOCTITE Plastics Bonding System

Loctite has been around longer than most of us have had a use for adhesives, in fact, in the 65 years they’ve been around they have become somewhat of a household brand. This should come as no surprise considering that they provide some of the best quality adhesives for virtually any application under the sun, which has seen their brand being used in hundreds of industries across the world.

Loctite has become somewhat synonymous with quality and ease of use, and their plastics bonding system for poly materials is no different. What they offer is a two-part permanent adhesive bond capable of securing both polyethylene and polypropylene surfaces with ease, and in true Loctite fashion, these bonds cure clear to provide a seamless connection between your workpieces.

The party piece of Loctite’s adhesive and activator pair is that they don’t require any clamping to work as intended, which means this works pretty much super glue or an epoxy resin in the way that it’s applied. This is awesome if you don’t have professional clamping equipment or simply don’t have the time to prepare and secure your workpiece beforehand, and let’s face it, who has that kind of time in modern-day life?

Keeping with the theme of saving you time, Loctite’s plastic bonding system dries in seconds and cures completely in minutes which they seem to be particularly proud of (and rightfully so). This in addition to their easy-to-use and re-sealable containers means that this is the ideal tool for quick repairs for contractors, artists, and DIY enthusiasts on the go.

If you’re looking for a product that’s easy to use, readily available, and has your back in a pinch, you can’t do much better for the price and availability of this adhesive. One noticeable drawback is that it’s sold in pretty limited volumes which isn’t ideal for bigger jobs, but on the other hand, finding these types of adhesives in larger volumes can be challenging (not to mention expensive).

- Bonds all plastic from Plexiglas, polycarbonate, and polystyrene to PVC

- Bonds leather, cork, paper, wood, fabric, metal, ceramic, and rubber

- Quick and neat with no mixing required

- Easy to use

- Versatile

- Dries and sets quickly

- Permanently bonds surfaces

- Creates a seamless bond

- No mixing needed

- Ideal for beginners

- Sold in limited volumes

- Cannot be used on some sheer surfaces

- No applicator provided

- Not ideal for larger workpieces

How to Glue Polyethylene and Polypropylene

Knowing that you can join polyethylene and polypropylene together can seem like a huge weight off your chest, and knowing which products are best suited for the exercise is even better. Although, if you don’t know how to go about it, all of the aforementioned is a bit pointless. This being said, let’s have a look at the best way to go about polyethylene gluing and polypropylene gluing respectively. Keep in mind that different products require different preparation, and others require none at all.

Prepare Your Surface

As we mentioned previously there are certain products that require preparation for the bonding process and others that don’t, but we recommend always preparing your surface to ensure the best poly bond possible.

How do you prepare a surface for polyethylene gluing? Well, much like you would prepare wood or metal you need to ensure that the surface that’s going to be bonded is clear of any contaminants like dust and grime. You can do so with a clean, damp cloth and then allow the surface to dry.

Once the surface has been cleaned and dried, use some fine grit sanding paper to lightly sand the workpiece to create some surface friction. Once you’re done sanding, wipe away any stray particles with a clean, dry cloth before moving on to the next step in the process.

Prepare Your Tools and Workspace

This can be different depending on the type of adhesive you are working with, they typically come in three varieties, but they all work pretty much the same way. Your options will usually be choosing between a one-part, two-part, and three-part poly glue system, each with its individual strengths and weaknesses.

Regardless of which one you chose, place all of the tools you will be using on the side of your dominant hand to ensure that you know where they are at all times. This also frees up space for your workpiece which should be located directly in front of you. Once you have your workpiece position the way you’d like, either flat or elevated depending on where and how you’d like to bond the two pieces together.

Place things like clamps and applicators on the opposite side of your adhesive products so they can be accessed quickly while working to ensure the best bond possible. Finally, ensure that you’re wearing some gloves, a face mask, and that you’re working in a well-ventilated area before moving on to the next step in the process.

Bond Your Polyethylene and/or Polypropylene

Believe it or not, this is the easy part (not to mention quite fun). If you are using a three-part bonding kit, apply the poly prep first, this works as a sort of primer to ensure that the workpiece receives the actual adhesive well.

These are usually solvent-based, so they dry really quickly. Once dry, apply the accelerator and use a heat gun on the polypropylene/polyethylene surface with a heat gun or hair dryer until it is hot to the touch. Once hot, apply your bonding adhesive to the second piece of material, line the two pieces up, and squeeze them together for about 10 to 20 seconds. Use clamps if required.

If you are using a two-part bonding adhesive you typically won’t have to prepare your workpiece. Simply apply the accelerator to one of the pieces you wish to join and allow it to dry out, then apply the adhesive itself to the second piece, line them up, and squeeze them together. Using clamps with two-part adhesives is rarely necessary because of how powerful they are, but it never hurts to be a bit cautious.

Should you find yourself using a one-part adhesive the process is even easier! These are actually just two-part adhesives that mix at the point of application, usually found in a dual syringe setup. If your workpiece has been prepared, simply apply the substance to one of the two parts being joined together, align them with one another, and squeeze them together for a good 10 to 20 seconds before clamping.

Now that you know what polyethylene and polypropylene are, what their applications are, their individual characteristics, how they can be bonded, what a good poly bonding glue looks like, and the best way to go about bonding these materials, it’s time for you to get out there and put your newfound knowledge to the test. Remember to check product reviews and ensure that you have prepared your workspace adequately before attempting to bond these materials.

Frequently Asked Questions

What Is Polypropylene Plastic?

What is polypropylene plastic? Polypropylene plastic is what is called a thermoplastic polymer. It is by far one of the most widely used materials on the planet due to its versatility and durability in most environments. It is derived from a monomer called propylene.

Is Polypropylene Plastic Good Quality?

Polypropylene is usually a really tough material, and it’s pretty flexible too which means you get the best of both worlds. It should come as no surprise then that this plastic and others like it can be found all over large- and small-scale engineering applications.

Is Polypropylene Toxic to Humans?

Even though most of us don’t know it, polypropylene is already all around us. Polypropylene is considered to be safe for human contact as long as it is not consumed or interacted with while being synthesized.