Polyester Resin vs. Epoxy Resin – Differences Explained

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Resin really seems to be peaking in popularity these days, with more and more professional artists and DIY weekend warriors discovering the ever-expanding applications of this amazing medium. This popularity also means that loads of people go into the medium thinking that all resin is the same and that their applications are somewhat universal. If you’re a veteran user of resin, you know that this is not the case, so let’s have a look at two of the most popular types of resin on the market, which are namely epoxy resin and polyester resin, how they stack up against each other, as well as what makes them distinct from one another and their given applications.

Table of Contents

What Is the Difference Between Polyester Resin and Epoxy Resin?

In the polyester resin vs. epoxy resin battle, there are many advantages and disadvantages to each of these resin types, but they also have their distinct applications. A main difference is that epoxy resin is far more versatile compared to polyester resin. This is due to it having inherent versatility, whereas polyester resin is more of a specialized tool designed for specific applications where something needs to be molded or formed rather than cast. Let’s dive a bit deeper into the polyester resin vs. epoxy resin battle to determine when and where each should be used.

Polyester Resin

Polyester resin is essentially a budget-friendly solution to a problem that would otherwise need an epoxy resin solution. This doesn’t mean that it’s inherently inferior, just that ir has a lower tensile strength, is less resistant to damage from chemical exposure, impact, abrasion, heat, and is, therefore, more applicable to “quick fix” applications.

It’s cheaper too, which means you can get a lot more of it for a lot less than you would with epoxy resin. In this instance, you definitely get what you pay for, therefore if the spot you’re looking to repair plays a big role in the overall structural integrity of your workpiece, this might not be the best choice in repair material. Does this mean that polyester resin is completely useless?

Absolutely not, polyester is the best choice when repairing any surface that will be finished with a gel-based substance, this is common in seafaring vessels like boats and catamarans as the finish often produces less drag compared to traditional finishes. This means that polyester works great as a body filler but cannot stand up to the punishment of exterior forces.

Overall, polyester resin has a very low resistance to water whereas epoxy resin pretty much dispels water on contact, so you could probably guess which one you would use in a water-rich environment. Polyester resin has pretty much the same complete cure time as conventional epoxy resin, but this does depend on your ambient environment including but not limited to humidity, heat, wind, airflow, and the amount of polyester being used to fill in the gap in question.

Something to keep in mind is the smell polyester produces, if you have an aversion to strong odors, we recommend dropping some extra cash for some epoxy resin. The smell of polyester resin is potent, to say the least, so always wear a respirator mask with the appropriate grade when making use of polyester resin.

- Cures hard

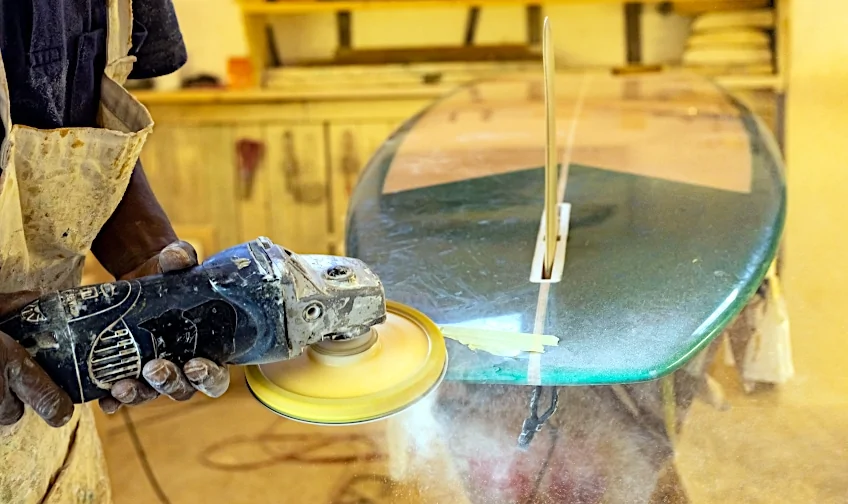

- Can be sanded, drilled, and buffed

- Scratches can be polished away

- Polyester can be bonded to polyester

- Compatible with gel-based sealers

- Affordable

- Not resistant to UV damage

- Not waterproof

- Not very durable

- Cannot be used as a sealer

- Primarily a filler substance

- Strong smell when curing

Epoxy Resin

Epoxy resin is then the popular choice for all of your repair and adhesive needs, mostly because it’s more versatile, sports a better tensile strength, has stronger adhesive properties, and tends to be more durable than polyester resin.

Being the most popular doesn’t mean much if you can’t get the job done though, and as much as it would pain fans of epoxy resin to admit it, there are certain things that it simply cannot do. Before we get into the specifics of what this resin can and cannot do, it’s worth taking a look at exactly what epoxy resin is and how it works.

What is epoxy resin? Unlike polyester resin, epoxy resin comes in two parts, namely the resin itself and the hardener. When the resin and hardener are mixed together, they undergo a chemical process that creates the substance we know as epoxy resin, which then bonds with the surface you apply it to while curing.

Epoxy resin is typically sold in two forms, namely deep pour and surface pour resin, these are intended for void filling and surface coating applications respectively, which is why it’s typically more sought after than polyester resin. Epoxy resin also happens to be really tough which is why it’s used as a protective layer on a wooden workpiece that is primarily stationed outdoors.

What makes it suitable for outdoor use though? Well, it essentially functions as a sealer that bonds with the wood’s fibers, this creates a protective layer of resin that shields the surface from impact, abrasion, moisture, excessive heat, UV damage, insect infestation, and many other exterior forces.

Although its credentials may be impressive, Epoxy doesn’t do too well when gel-based sealers are applied to it, and when gel-based sealers need to be used you are always best off going with a polyester sealer. Epoxy resin is also noticeably more expensive in larger volumes than polyester resin which means that covering larger surfaces can be significantly cheaper when using a polyester resin.

So, it’s cost-effective, relatively simple to apply, readily available, and pretty durable. This pretty much sums up epoxy resin, but it can be noticeably more challenging to shape, mold, tap, and sand compared to polyester resin which is why it’s not used as a filler quite as much as polyurethane resin is. Dry and cure times between these two types of resin are pretty similar, although epoxy produces far fewer fumes and doesn’t smell nearly as bad as polyester resin does.

- Easy to use

- Versatile

- Water, heat, abrasion, impact, and insect resistant

- 100% food-safe when completely cured

- UV safe

- Adhesive strength is 20% stronger than polyester resin

- Can be used as a filler and surface coating

- Contains multiple volatile organic chemicals (VOCs)

- Cannot be used with gel-based finishes

- Not as malleable as polyester resin

- Expensive in larger quantities

What Can These Resins Be Used For?

What is epoxy resin used for? What is polyester resin used for? Since we know what these substances are and a few of their characteristics, let’s have a look at a few of their most common applications and where you might find them in your day-to-day life, as well as the specific industries they serve in.

What Is Polyester Resin Used For?

The polyester resin might seem like the inferior option given the choice between epoxy and polyester, but in reality, you could get a lot more bang for your buck using polyester resin than you would epoxy.

Polyester resin is also known as fiberglass resin, this is because fiberglass resin and polyester resin are basically the same things, with the latter being slightly different on a molecular level, but the two essentially look, smell, and function the same way. What can fiberglass resin be used for, you ask?

Well, we’ve already mentioned that it can be used for boat repair due to it being far cheaper to purchase in bulk compared to epoxy resin, but it has some other useful applications too. A good example of this is molding, it is used in a number of different industries to make high-quality molds for sensitive materials and can even be found functioning as a toner in laser printers, which is pretty cool.

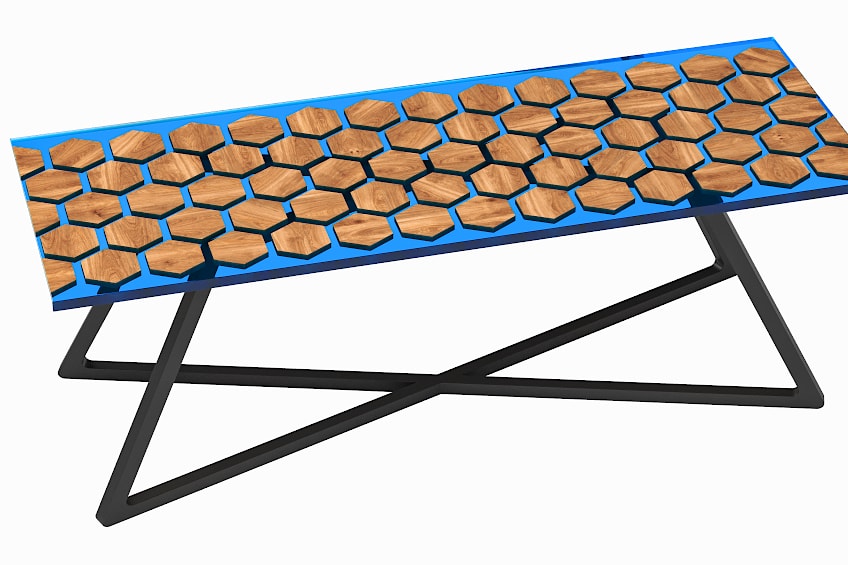

Fiberglass resin can also be used to create smaller things like jewelry. You could find polyester resin being used in things like home improvement, aircraft manufacturing, certain appliances, and even furniture if you looked hard enough.

Because polyester resin is so malleable, it can even be used in the construction of ponds and lakes with the correct sealer, plus you have the added advantage of being able to use this material with dyes and colorants, although this will affect the final cure and dry time of the material. In fact, its dry and cure times can be adjusted by altering the ambient temperature and introducing certain additives to complement your working time.

What Is Epoxy Resin Used For?

Epoxy resin is hands down the more versatile of the two materials and has been used in a number of industries for decades. Why? Epoxy resin is strong, has a relatively fast curing time, has strong adhesive properties, and is resistant to virtually all forms of wear and tear. This being said, let’s have a look at exactly where epoxy resin is used and what you could use it for should you be in the mood for some crafting.

Epoxy resin has been used most notably in recent years for crafting, both commercial and private as an affordable means to create objects that would usually require the services of a professional artist or 3D printer.

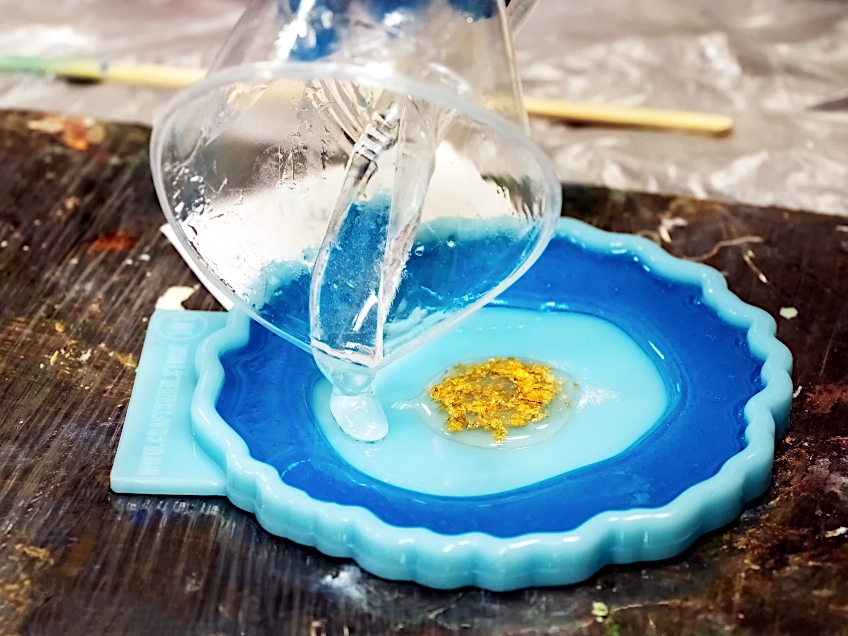

As we’re sure you’re aware, this is known as casting, and it simply involves mixing together some resin and hardener in equal amounts and mixing them together. Once your resin has been mixed together it can be poured into a mold and allowed to cure, and once cured you should have a completely identical form to that of the mold.

This method of replication is so effective that it’s sparked an entire industry of epoxy resin creations through the sale of DIY kits that allow you to castings like jewelry, coasters, cups, plates, 3D shapes, keyrings, cutting boards, photo frames, book covers, clipboards, toys, automotive parts, and even smartphone covers!

The best part? These are just things that you can cast with epoxy resin, which you would use what is known as “deep pour” resin to create. The second type of epoxy resin, known as surface pour resin, has even more uses. It can be applied to wood, metal, or plastic surfaces to create a protective barrier between these surfaces and their immediate environment. The result is an impact, abrasion, heat, moisture, and rot-resistant coating that will likely last for the lifetime of the surface it’s been applied to.

If you wanted to take the latter application of epoxy resin to its logical extreme, you could use it to seal things like countertops, stone flooring, and even entire walls if you could get your hands on enough of it. You should keep in mind that it can be quite costly to surface epoxy resin in those volumes, and it can be quite challenging to apply too.

| Polyester Resin Applications | Epoxy Resin Applications |

| Airplane construction | Sealing Surfaces |

| Boat repair | Heat resistant adhesive |

| Toner in laser printing | Food-safe surface coating |

| Home improvement | Protective coatings for wood and metal |

| Automotive repair | Automotive insulation and repair |

| Jewelry creation | Jewelry creation |

How to Use These Types of Resin

Now that you know what the differences are between these two types of resin and what you can do with them, it would be good if you knew how to use them too. Although it might seem a bit intimidating, the resin is pretty simple to use and we’re certain you’ll have the hang of it in next to no time with just a bit of practice and preparation. This being said, let’s have a look at how to use fiberglass resin and how to use epoxy resin.

How to Use Fiberglass Resin

Using fiberglass resin might sound a bit scary considering how fiberglass, in general, has been portrayed as a safety hazard, but you should know that it’s perfectly safe as long as the correct precautions have been taken.

Prepare Your Workspace

When working with any resin it’s really important to prepare your workspace well. Remember that resin is viscous and if you will and it can be a bit of a challenge to clean up, so cover any surfaces you won’t be coating with a tarp or some old newspaper. Next, ensure that your workspace is well-ventilated or ideally outside if the weather isn’t too cold. Fiberglass or polyester resin smells pretty bad so this step is both for your safety and comfort.

Prepare Your Tools

To get your resin mixture, you’ll need a plastic measuring container, a brush, a roller, your resin, and a catalyzing hardener for your fiberglass resin. Before you get started ensure that you have some gloves graded for use with resin, as well as a face mask and eye protection ready. Resin is harmless once cured but it can cause serious discomfort if it ever comes into contact with your skin or hands while unmixed.

Prepare Your Resin

Now for the tricky part. Fiberglass resin, unlike epoxy resin, needs to be mixed in certain percentages to get a decent curing time and consistency, so check your manufacturer’s instructions regarding how much resin and catalyst you’ll need to get a decent cure time.

The packaging will give indications of which ratios are ideal for which temperatures, so pour the exact amount of resin you’ll be needing into the plastic cup, add your hardener, and mix it thoroughly with a mixing stick. Finally, apply your resin to your workpiece using your brush or fine nap roller and allow it to cure for the manufacturer’s recommended time period.

How to Use Epoxy Resin

Epoxy resin is slightly less particular in its application process compared to polyester resin. For this exercise, you will need a plastic measuring container, a brush or roller, a mixing stick, your resin, your hardener, and maybe a few clothes just in case things get messy.

Prepare Your Workspace

Before you find out how to use epoxy resin, you should prepare your workspace. Much in the same way you did with the polyester resin, lay down a tarp or old newspapers in the workspace you’ll be using the resin in, as well as on any surfaces you don’t want the resin to accidentally get splattered on. Ensure that your workspace is well ventilated and that you have all of the tools we mentioned previously at the ready.

Prepare Your Tools

A neat trick when preparing your tools and workspace before working with epoxy resin is placing everything you’ll be using on the side of your dominant hand, with your measuring container directly in front of you. This ensures that you always know where things are and keeps your workspace uncluttered. Finally, ensure that you have a face mask, eye protection, and gloves graded for use with resin fitted before moving on to the next step in the process.

Prepare Your Resin

Now for the fun part. This process isn’t nearly as challenging as it would be with polyester resin. The mixing ratio for epoxy resin is 1:1, or in other words, equal parts resin, and hardener. Simply pour the same amount of resin and hardener into the plastic container and mix them together using the mixing stick. Once you’re satisfied with the mixture, use a brush or roller to apply your resin to the workpiece and allow it to dry for the manufacturer’s recommended time period.

Now that you know what the difference between epoxy resin and polyester resin is, what their characteristics are, where they are used in both DIY and commercial industry, and how you can use them for yourself, it’s time for you to go out there and put your new-found knowledge to the test. Remember to always work in a well-ventilated area and always wear the appropriate personal protective gear when working with resin.

Frequently Asked Questions

What Is Fiberglass Resin?

What is fiberglass resin? Fiberglass resin and polyester resin are essentially the same things. Although there are small differences between the two, they are used for virtually the exact same applications such as aircraft manufacturing, boat repair, jewelry creation, automotive engineering, and many other facets of industry.

Can I Mix Acrylic Paint with Resin?

There are many means of adding color to epoxy resin, but one of the best ways to do so is by using acrylic paint. There are other means such as food coloring and mic powder but adding some swirls of acrylic paint to your epoxy resin makes for a unique aesthetic.

Is Epoxy the Same as Polyurethane?

Although these two might seem similar in appearance they are fundamentally different on a molecular level, and how they react with their catalysts during the curing process. Polyurethane is typically a lot stronger than epoxy and therefore has a wider range of applications.