What Is Spar Urethane? – Flexible Exterior Varnish Guide

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Sealing wood is an essential part of any wood project, as it protects the material from moisture build-up, wood rot, and so on. However, we have seen a variety of products come and go, many of which have promised us excellent results, only to fall short. Fortunately, spar urethane has proven to be a viable option when it comes to big or small sealing jobs. Below, you will find out how to apply spar urethane and everything else that you need to know about it!

Table of Contents

Explanation of Spar Urethane

Among the most common questions we get is “What is spar urethane?”. This question is often presented by those that are unfamiliar with various sealing products. You will be forgiven for thinking that spar urethane and polyurethane are the same thing. However, both of these compounds have distinct features that make them distinguishable from each other.

Spar Urethane is the ideal finish for wood that will be exposed to harsh climactic conditions. In addition, the durability of spar urethane means that it is also the best option for use on wood that may be difficult to reach or refinish on a frequent basis. These benefits are reflected in the cost of this product, so it is generally regarded as a specialist high-performance exterior wood finish.

Spar urethane is different from traditional wood varnish in two ways. First, it has a significantly higher blend of oils and solvents. Secondly, it has a variety of additives that have been blended into the formula which makes it highly flexible and resistant to UV light.

Definition of Spar Urethane

Spar urethane gets its name from the spars on a ship. These are the wooden poles that are used to support sails. Naturally, these structures are exposed to incredibly harsh weather, as they are constantly exposed to moisture and direct sunlight. This means that spar finishes not only had to be durable, but also extremely flexible to withstand the constant expansion and shrinkage of the wooden spars.

This flexibility is achieved by the high oil content of spar urethane and is what sets this type of sealer apart from other types of varnish.

Chemical Composition of Spar Urethane

The chemical composition of spar urethane is an important factor to consider, more so if you are planning to use it in your home. Most spar urethane products are manufactured with alkyd resins and phenolic-modified alkyd resins. Alkyds are polyester resin that has been modified by adding fatty acids and a series of other components.

Essentially, spar urethane is a blend of spar varnish that has had urethane added to it. However, we do not suggest trying to purchase raw materials and creating your personal blend of spar urethane, as it is not that simple. This is because the oils that are used are either linseed or tung, while the resins that are added would consist of either polyurethane, phenolic, or the aforementioned alkyd.

The resins used in spar urethane act as hardeners, with phenolic and alkyd resins usually used in varnish wood finishes. The amount of resin in a product will determine if it is best for interior or exterior use. Interior wood finishes will generally have a lower oil content and a higher resin content, with the opposite for exterior wood finishes.

Another vital component of spar urethane is the solvents that are added. These essentially allow the oils and resins that were added to be dissolved. There are different types of solvents available, but in this case, paint thinner and mineral spirits are among the most common components that are used. Additionally, solvents such as xylene and naphtha are also used for quick-drying products. The reason for the addition of solvents is to make it easy for us to apply resins and oils by thinning them.

When it comes to the most important layer of protection UV blockers are a crucial component for protection from the sun. Any stain that does not have a UV blocker will not do well when applied to an exterior project. This will essentially allow the wood to dry out and break, which is the last thing that you need.

Properties of Spar Urethane

As we have already established, spar urethane was named after the poles or spars that this substance was initially applied to. While it is no longer exclusively used on ships, this polyurethane wood stain is known to protect the wood while providing an excellent finish.

| Properties | Spar Urethane | Polyurethane |

| Cost | Expensive | Cost-effective |

| Drying Time | Quick-drying | Takes a longer time to dry |

| Weather and UV Resistance | Outstanding weather and UV resistance | Newer formulas are very good; however, older forms are not |

| Hardness | Very hard | Not as hard, but still quite tough |

| Flexibility | Low | High |

Durability

With proper maintenance, you can easily get 10 to 15 years out of a spar urethane coat. Unlike polyurethane which will need to be applied periodically, you will only need to apply one coat of spar urethane. Due to the overall durability of spar urethane, it is perfect for outdoor use. This is because it has a variety of additives that are UV-resistant and it is more flexible than standard polyurethane.

This means that it is able to contract and expand with various changes in temperature, which wood is prone to do. This avoids cracking and chipping under harsh conditions, which is what makes it the preferred choice when it comes to long-term finishes.

Resistance to Water and UV Light

One of the reasons why spar urethane is such a desirable finish is because of its resistance to water at all temperatures. This includes snow and rain, which is perfect for intense temperature changes. Spar urethane provides a beautiful clear finish that is also waterproof and UV-resistant. Since this is a compound that was formulated based on the harshest conditions, it is perfect for outdoor use.

Gloss Retention

When it comes to any finish, you will need to ensure that the gloss is able to last a long time. Unlike other finishes, spar urethane is able to maintain a glossy finish for many years without you needing to add more coats over time.

Flexibility

The flexibility of spar urethane is something that is desired in most finishes. While standard varnish is prone to chipping and cracking over time, spar urethane has incredible flexibility which is perfect for all types of conditions. This means that it is ideal for outdoor use as it can handle any type of conditions that are thrown at it.

Types of Spar Urethane

Before we take a look at the types of spar urethane that are available, you would need to understand the advantages and disadvantages of each one. Below you will find a table that features a comparison of oil-based vs. water-based spar urethane.

| Properties | Oil-Based Spar Urethane | Water-Based Spar Urethane |

| Color | Slight yellow tint | Clear |

| Durability | High | Average |

| Hardness | Very hard | Average |

| Weather resistance | High | Low |

| Volatile organic compounds (VOCs) | High | Low |

Oil-Based Spar Urethane

For a long-lasting finish, oil-based spar urethane is the best choice, especially for outdoor use; however, it does come with a handful of disadvantages that you would need to consider before using this product. Oil-based spar urethane has more fumes, which means that it is more combustible while being significantly less environmentally friendly.

Being an oil-based product means that it is significantly more resilient than its water-based counterpart. This includes a series of benefits such as UV and water resistance while also being capable of contracting and expanding when exposed to different temperatures. Additionally, oil-based spar urethane takes more time to dry, and applying more than one coat can take a long time.

Oil-based spar urethane is perfect for areas with a lot of moisture, but it is also resistant to a range of other solvents such as grease and oil. You can also expose this compound to high temperatures, which is great for kitchen counters. However, as we have mentioned before, this compound can be incredibly harmful, and short-term exposure will lead to dizziness, headaches, nausea, and eye irritation.

In the worst-case scenario, long-term exposure to spar urethane will result in cancer, and damage to the central nervous system, kidneys, and liver. While this sounds really bad, you will be able to safely use this product without any issues. All you need is a high-quality respirator and ensure that you are working in a well-ventilated workspace.

Water-Based Spar Urethane

This product is essentially everything that its oil-based counterpart is not. However, despite being significantly more environmentally friendly, it lacks the ability to produce a long-lasting finish. However, this product is better suited for indoor use as it dries quickly and it emits less VOCs.

Despite not having the protective qualities of oil-based spar urethane, this product has its place in workshops and homes. Furthermore, if you are looking for a quick and easy finish that will provide short-term protection, then this is the right product for you.

Advantages of Spar Urethane

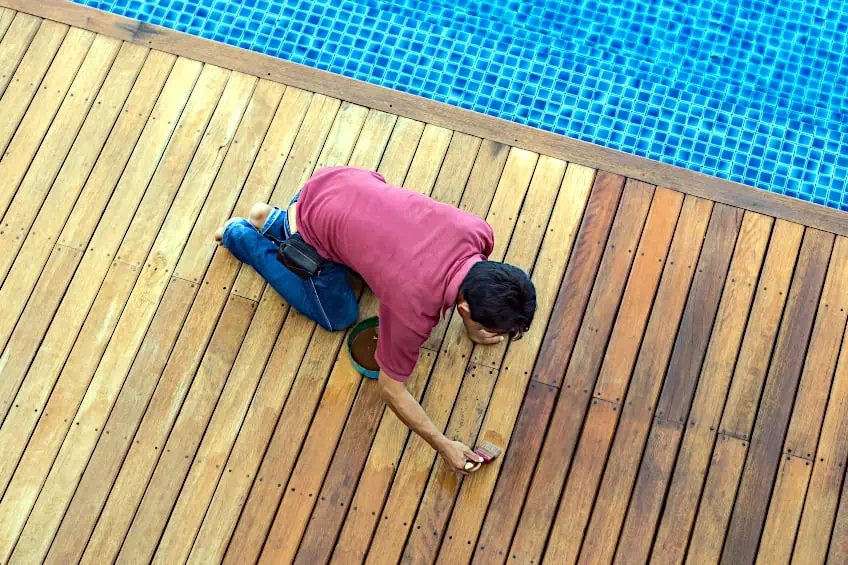

If you have ever wondered what is spar urethane used for, you will generally find it being applied to exterior wood surfaces. This proves that it is known to be a long-lasting finish, but there is a range of additional benefits that come with using this product. This includes the long-term cost, ease of application, overall longevity, and protection from weathering and aging.

Protection from Weathering and Aging

A wood finish that can easily withstand all elements is often sought-after, and if this is what you are after then spar urethane is an excellent choice. Regardless of whether you are planning to use it in your sunroom or on your roof, you can be assured that you will have a long-lasting finish. The resins that have been added to the spar urethane have determined its hardness, which will protect the wood from snow, rain, and intense sunlight.

Most modern spar urethane products are also very flexible while maintaining weather and UV resistance. This means that the wood is able to contract and expand in different conditions which will protect it from breaking.

Longevity of the Finish

When applying a few coats of spar urethane, you can expect to enjoy between 10 and 15 years of protection if proper maintenance is applied. If your surface is peeling or cracking to some degree, you can sand it down and apply a fresh coat of spar urethane. Overall, the longevity of the finish comes down to your understanding of how to apply spar urethane.

Ease of Application

Spar urethane, particularly the oil-based variation, takes a bit of practice to apply without any bubbling or visible brush strokes. However, you can use a variety of tools to apply the finish such as sponge brushes and cloths. Since spar urethane is a thick finish, you can use mineral spirits to dilute it by 50% and then use a cloth or rag to apply it. However, you will need to apply twice the amount of coats since you have thinned the product.

Cost-Effective in the Long Run

Upon purchasing, you will find that spar urethane is much more expensive than any of its alternatives such as polyurethane. However, it has a much higher level of durability which will result in a long-lasting finish. While polyurethane is cheaper, you will need to eventually reapply it and maintain it more often.

Spar urethane offers better value for money over a longer period.

How to Apply Spar Urethane?

We have briefly touched on the application process of spar urethane; however, there is a lot more that goes into it. This can be a tricky substance to apply, especially if you are opting not to dilute it. Due to its viscosity, it is prone to bubbling and if you choose to use a paintbrush to apply it, you will have issues with streaks in the finish. Below we have provided all of the information that you would need when it comes to using spar urethane.

Surface Preparation

Before you can jump into applying spar urethane to the surface, you should ensure that the wood is smooth. This can easily be done by sanding with the grain using 120- to 150-grit sandpaper. Once completed you will need to ensure that the surface has been completely cleaned.

You can remove sawdust with a cloth that has been dampened with mineral spirits or you could use a vacuum. If you have used putty or filler, you will need to ensure that they do not contain any wax and they would need to be completely dried before you can apply the spar urethane.

Application Methods

When applying spar urethane, you should be mindful of the viscosity of the product. It is advised to use a bristle brush to apply the product; however, if you choose to dilute spar urethane then you would have more available options. By thinning spar urethane, you will then be able to apply it with spray or apply it with rags.

The process of diluting spar urethane is very simple, all you will need to do is dilute the substance with mineral oil up to 50%. This will make it significantly easier for you to apply spar urethane to the surface of the wood without bubbling or leaving behind brush strokes that are nearly impossible to get rid of without sanding.

Brushing

Brushing is the most common method of applying spar urethane to a surface and it is also the simplest method available. However, we have already discussed why this is not always the best method as you could leave brush strokes behind. This means that you will need to sand the surface once it dries to remove the unwanted texture.

The good news is that you could get away with using a sponge brush. While not a drastic improvement, it is a better option compared to a standard paintbrush. We highly recommend diluting spar urethane before trying to apply it with a brush.

Spraying

By thinning spar urethane even more you will be able to spray it onto the surface of the wood via a High Volume Low Pressure (HVLP) spray gun. By spraying, you will be able to cover a larger surface area in a shorter time frame, but the caveat is that you could miss parts of the surface and you could also run into issues when it comes to cleaning the spray gun. By spraying, you will also need to add more coats as you have diluted the spar urethane.

Wiping

Wiping would be the ideal method of applying spar urethane to a surface as it allows you to cover the surface of the wood in a smooth coating. Not only is this a beginner-friendly method, but you will also be able to abandon the use of paintbrushes, which means that you will have less clean-up time.

For the best results, dip your cloth into the diluted spar urethane and apply thin and even coats across small sections of the wood. By doing this, you will ensure that no spots have been missed and that the coat remains even. Since you are applying thinner coats, your drying time will be shorter as well.

Drying and Curing Time

Knowing the curing and drying time of spar urethane is important as this will allow you to add another coat after sanding. To find out if the surface has fully dried, put your hand on the surface and if it feels smooth and hard without leaving any fingerprints behind, then it is completely dry. Oil-based spar urethane takes between 12 and 24 hours to completely dry, but we recommend waiting the full 24 hours before sanding and applying another coat.

Sanding and Reapplication

Once you have waited the 24-hour period, you will need to ensure that you sand the surface before reapplying another coat. By waiting 12 hours, you can apply a fresh coat without sanding. 220- to 320-grit sandpaper will be needed to achieve a smooth surface after the final coat has been applied. If you have sprayed the surface with an HVAC system you will need to use 400- to 600-grit sandpaper.

Another benefit of spar urethane is that you do not have to sand in between coats.

Spar Urethane vs. Polyurethane

The question of how spar urethane compares to polyurethane is is one of the most commonly asked. The reality is that spar urethane is a better exterior finish and polyurethane is better for interior use. This is mainly due to the superior flexibility and durability of spar urethane. While polyurethane is more brittle and likely to flake off when the wood it has been applied to expands and contracts, when used in interior spaces, it produces an excellent, long-lasting finish that has a polished look to it. Polyurethane is also able to stand up to chemicals very well, which makes it perfect for a table or countertop that will see frequent cleaning.

Now that you have a clear understanding of spar urethane, you will be able to use what could be argued as the best exterior sealant for your wood. While spar urethane can be a very dangerous sealant when used indoors, when the proper safety precautions are taken it is a safe and simple process. Good luck with your woodworking project!

Frequently Asked Questions

What Is Spar Urethane?

This is a long-lasting wood finish that was traditionally used on boats and ships. This was able to protect the spars of these vessels from harsh sunlight, rain, and any other type of weather.

What Is Spar Urethane Used For?

Spar urethane is generally used for outdoor projects such as windows and doors. While spar urethane can be used indoors, it is better to use a water-based finish that emits fewer VOCs.

Is Polyurethane Superior to Spar Urethane?

Both of these products have their place. Polyurethane needs more coats to achieve the same level of protection; however, it is better to use indoors. Spar urethane is an ultra-durable substance that can easily resist the most severe weather, making it ideal for outdoor use.