What Is CA Glue? – Everything to Know About Superglue

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

We have used adhesives for thousands of years in one form or another. They provide us with a quick and effective means of adhering things to surfaces, fixing broken objects, and a viable alternative to conventional fasteners like screws and bolts. Some adhesives tend to be more popular than others, with one of the most popular being CA glue. What is CA glue, though? Let’s have a look at what CA wood glue is, how it works, what it is used for, and what makes it one of the most popular adhesives on the face of the planet.

Table of Contents

What Is CA Glue?

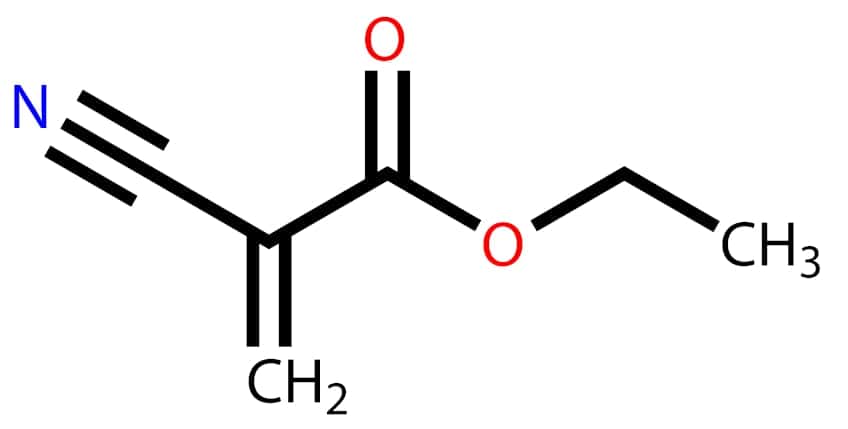

CA glue is an abbreviation for the adhesive substance known as cyanoacrylate. Colloquially, this glue has a few names, including but not limited to crazy glue and super glue. Cyanoacrylate is exceedingly easy to use and happens to be one of the most versatile adhesives on the market, being able to join and hold most materials with minimal preparation, effort, and time.

Aside from craft glue, CA glue is often one of the first adhesive substances they’re introduced to throughout their lives. Superglue is commonly used to repair children’s toys, create school dioramas, stick photographs to memory boards, and even repair broken shoes and jewelry. Even if you aren’t familiar with other adhesives, you’ve probably heard of and/or used CA wood glue before.

Aside from its versatility, there are a few reasons why CA glue is so popular. For one, it dries quickly, which makes it the ideal tool for quick repair scenarios or emergency situations. It is also a one-part adhesive which means it can be deployed quickly without having to measure, mix, and apply it using a special applicator. As you can see, the convenience of CA glue is a big part of its appeal.

The bond the high-quality CA glue products create is also impressively strong. A high-quality superglue can form bonds that last for years even though the glue is not intended for permanent repair work. It is also resistant to a whole host of exterior forces with a few exceptions, making it robust as well as versatile.

How CA Glue Works

CA glue is known for its impressive strength and durability. How does it achieve this though? Well, put simply, CA glue is different from most other adhesives. While other commonly used adhesives are water-based, CA glue is based on an acrylic resin, specifically cyanoacrylate which turns from a viscous liquid into a hard plastic once it has dried and cured completely.

Cyanoacrylate is an acrylic monomer and is the core of super glue’s strength and fast dry times. Cyanoacrylate needs special drying/curing conditions to function as intended, specifically needing the presence of moisture to form a molecular bond with the surface in question. Whether it is liquid water or ambient humidity, cyanoacrylate will use it to form an impressively strong bond.

That being said, CA glue will not be able to bond with a surface if it has been perfectly dried. However, when moisture is present, it uses it to create bonds by forming molecular chains between itself and the surface in question. Unlike other adhesives that require the evaporation of solvents to solidify, CA glue requires at least some amount of moisture to dry and cure correctly.

If you are considering using CA glue for your next project, you should consider the conditions your workpiece will be subjected to if your surface is completely sheer and lacks moisture entirely the glue isn’t likely to work very well. That being said, once the glue has had a chance to cure completely, I should be able to take quite a bit of punishment without losing adhesion.

The History of CA Glue

Like most great inventions, CA glue came about as a response to a need. Namely, the need for durable plastic sights for guns. You see, CA glue was accidentally discovered by Dr. Harry Wesley Copper while he was attempting to produce a plastic that could be used to create gun sights for soldiers during the second world war. Pretty cool right?

Well, cyanoacrylate was way too sticky to be used in the creation of those gun sights, so the discovery was shelved until the doctor needed a substance that wasn’t affected by heat in order to create jet canopies. Even though Copper discovered cyanoacrylate in 1949, he wouldn’t sell or market the product until 1956, when it was sold under the name Eastman 910.

Cyanoacrylate was patented under the name Alcohol-Catalyzed Cyanoacrylate Adhesive Compositions/Superglue at the time, and eventually, the Eastman 910 name would fall away making way for the name we all know and love today, Super glue! So, if there were other adhesives around during this period, what made cyanoacrylate so special?

Put simply, the good doctor’s discovery did not need any heat or pressure to form objectively superior bonds with the surfaces it came into contact with. No heat and no pressure meant it could be applied in virtually any environment quickly, and since it dried quickly too, it quickly became an extremely popular tool to have around.

Superglue As Liquid Sutures

Since superglue was only discovered toward the end of the second world war, it never got the chance to be implemented in the field. However, the Vietnam war soon arose and superglue played an integral part in the survival of US troops on the ground. You see, superglue has another characteristic that sets it apart from other adhesives; it is almost completely non-toxic. How did this benefit the troops though? Well, the jungles of Vietnam have high degrees of humidity and while these are not ideal conditions for wound healing, superglue binds flesh quickly.

How do you treat deep lacerations and bullet wounds out in the humid jungle environment? By pouring superglue directly onto the affected area. That’s right, superglue can function as a liquid suture when needed, stopping profuse loss of blood while ensuring that the wound would not get infected. Field medics from this era have been reported saying that superglue had proven to be an indispensable tool when stabilizing wounded soldiers in the field.

Even Dr. Cooper himself is reported as saying that superglue is very powerful and that the fact that it had saved so many lives is something that he was very proud of. Considering that his initial intention was to allow soldiers to fire more accurately in order to kill the enemy, but ended up saving tons of lives instead, is quite an interesting and somewhat heart-warming historic fact.

How Does CA Glue Differ from Other Adhesives?

How does CA adhesive differ from other adhesives? Historically, adhesives work by shedding moisture once they have been applied to their intended surface, or need to be combined with a catalyst in order to cure and harden. Generally, glues harden either by allowing the solvent in their composition to evaporate or by undergoing a thermic reaction with their catalyst.

CA glue stands apart from both of these, well sort of. CA glue doesn’t need to have its solvent evaporate to harden because it doesn’t contain any solvent. CA glue is also a one-part adhesive which means that it does not need to be combined with a second substance in order for it to dry and cure. Well, at least not in the same way that adhesives like epoxy resins do.

CA adhesive does have a catalyst, the only difference being that instead of its catalysts being in a tiny tube that you have to painstakingly squeeze out and mix before it can be used, cyanoacrylate glue’s catalyst is in the air (most of the time). Cyanoacrylate glue uses moisture (whether airborne or liquid) to catalyze and harden once it has been applied.

Have you ever left a bottle of superglue open because you lost the cap only to come back and find that the entire bottle has hardened? This is because the glue has been exposed to moisture in the air, causing it to harden inside the bottle, and effectively rendering it useless. This is why it’s super important to close your superglue containers after use and store them correctly.

Drying, Curing, and Safety

CA glue also differs from other adhesives by not needing any heat or pressure to be used effectively. White wood glue requires your workpieces to be clamped in order to form a strong bond, and two-part epoxy adhesives require a thermic reaction and certain temperatures to form a perfect bond with their intended surface.

CA glue is also completely safe to use when it is in liquid form and once it has been cured. Does this mean that you should go around eating superglue? No. However, it does mean that superglue can be used safely on items that will come into contact with food without damaging your skin or poisoning you.

That being said, you should use superglue in the well-ventilated environment as the fumes produced while in liquid form can be overwhelming, especially if you have respiratory illnesses.

What Is CA Glue Used For?

As you can imagine, glue as versatile and robust as CA glue has quite a few uses. Many industries and individuals use this glue on a near-daily basis, so let’s have a look at where and how CA glue is used and why it makes for the perfect tool for these applications. There are many more applications for CA glue, and we’re sure you can think of a few creative ones too!

Woodworking

Using CA glue for woodworking is the perfect example of how strong and versatile CA glue can be. After all, if you need a strong and fast-acting adhesive to hold different parts of your workpiece together, there aren’t many better options for the job. CA glue is more than capable of holding together and even permanently suspending small to medium-sized wooden workpieces.

CA glue is really effective on solid wood surfaces due to the porosity of the material. The glue seeps into the pores of the wood, catalyzes with any moisture present, and creates a strong adhesive bond. CA glue also works well on engineered wood surfaces like veneer, particle board, and MDF (medium-density fiberboard).

How does one use CA glue for woodworking? Well, it can be used to bond two pieces of wood together without the use of fasteners, which means you won’t have any screw heads sticking out of your surface. It can also be used to glue wood to other materials like metal and plastic, which is perfect for mixed media art pieces and even some types of engineering projects.

Electronics

CA glue can also be used in the repair or adhesion of electronic components. How? Well, CA glue is not a conductor which means that you don’t run the risk of your electronics arcing or otherwise shorting out. This glue can be used to secure both insulated wirings and to ensure that the covers of electronic devices are firmly closed.

If you have ever gotten your smartphone back from the repair store and noticed that it smelled a bit like superglue, that’s likely because certain grades of CA glue can be used to seal electronics safely. They can also be used to spot repair electronics like the plastic control boxes for LED or RGB lighting units that have been cracked or broken.

Medical

We mentioned CA glue for sutures earlier, but there are other examples of CA being used for medical applications beyond this. Even if a wound is not fatal, you can still use CA glue to neatly close a wound to ensure that it does not get infected. When superglue is not being used to seal wounds, there are some other useful applications for it in the medical field.

For one, it can be used to bond and coat the interior joints of medical devices. It can also be used as a fastener on one-use objects like face masks, catheters, needles, and even cannulas. It can even be used in emergency care devices like tubes used to resuscitate a patient, filters for blood transfusions, and even oxygenators! These do require the use of medical-grade superglue though.

Advantages and Disadvantages of Using CA Glue

There are many advantages to using CA glue in your everyday life, so we thought we’d lay out a few of them for you to consider. Superglue is highly versatile, it is extremely strong, can be used in almost any environment, and since it dries quickly it can be deployed immediately.

Superglue is also mostly clear so it will not take away from the look of your workpiece or obscure the surface once applied.

There is no such thing as the perfect material, so let’s have a look at some of the downsides of using CA glue. While it might dry quickly, this means that your workpiece will need to be lined up perfectly before applying it. It can also be a nightmare to get off your fingers or clothes if you accidentally get some on you, so be careful when applying it. Keep in mind that superglue also cannot be applied if there is no moisture present on the surface of your workpiece or in your immediate area.

- Dries quickly

- Can be deployed immediately

- One part adhesive

- Dries clear

- Does not obscure the surface of your workpiece

- Can dry too quickly for you to make adjustments

- Can be tricky to get off if you get some on your hands

- Cannot catalyze if there is no moisture present

- Will dry out if the cap is left off the container

Tips for Using Superglue Effectively

While simply squeezing your superglue out of the container onto your workpiece there are a few things you can do to ensure that the bond is extra strong. Here are a few steps you can follow to ensure that the bond between your superglue and the surface of your workpiece is as strong as possible the next time you need it.

Rough Up the Surface

When using any adhesive it’s always best to ensure that there is as much surface friction as possible. Using some medium-grit sandpaper, sand the surface of your workpiece lightly, making it just slightly scuffed.

This should give the glue a good amount of surface friction to bond with the surface nicely.

Clean the Surface

Cleaning the surface of your workpiece is important because the glue will adhere to any dust, grime, and/or mold present on the surface once you apply it. You can either wipe the surface off with a clean cloth to ensure that any sanding dust has been removed or you can give the area a good once over with a wet cloth.

Apply Your Superglue

As you can see there isn’t much preparation to do. All that’s left is to apply your super glue. Remove the cap from your superglue tube and carefully squeeze out the amount you need both around the perimeter of the contact area as well as in the center.

Once applied, quickly place the second part of your workpiece in contact with the target area and hold it there for the time period indicated by the manufacturer. Finally, replace the cap of your superglue tube.

Different Types of CA Glue

There are various types of CA glue on the market, but they’re all essentially different variations of the cyanoacrylate formula. These have been formulated to suit different applications and work particularly well on certain surfaces.

If you are going to be using superglue it’s best to familiarize yourself with the different types available to you so you always choose the best tool for the job.

Medical-Grade Cyanoacrylate

The name pretty much says it all. This type of cyanoacrylate can be used either in medical environments, on medical instruments, or invasively to seal wounds. This grade of cyanoacrylate can be quite expensive so we wouldn’t recommend using it to fix a broken handle or TV remote if that’s all you need superglue for.

Rubber and Plastic Cyanoacrylate

This glue has been specially formulated to work on rubber and certain kinds of plastic that have been derived from oil-based substances. The next time you have a leaky hose or a broken plastic container you can be sure that this type of cyanoacrylate has your back. This is far cheaper than the medical-grade stuff and often lasts quite long once applied.

Intensive-Grade Cyanoacrylate

If you’ve been struggling to repair something using fasters or other one-part adhesives then this might be just what you need to get the job done. Being as close to industrial grade adhesives as possible, this type of cyanoacrylate will hold and secure metal, plastic, wood, rubber, and even type of glass if you need it to.

As you can imagine, it’s a bit more expensive than the rubber and plastic version.

Rubber Toughened Cyanoacrylate

While regular cyanoacrylate is tough, if you’re going to be fixing/adhering to a workpiece that will be actively used while being exposed to things like impact and abrasion, this is what you want. This type of cyanoacrylate is more flexible, bendable, absorbs shock, and is even more temperature resistant. If you don’t want to use an epoxy, this type of superglue is a great alternative.

How to Choose the Right Superglue for You

Now that you know there are different types of superglue out there for all manner of applications, you might be wondering how to choose the right one for you. If you are, we’ve listed a few points you should take into consideration when next trying to choose between the many superglue variations available today.

Viscosity

When using any adhesive, the viscosity will greatly impact how user-friendly the glue is in any given scenario. If you have a large surface to cover and the glue is really runny, this can create a mess. If you have a really small surface to cover and it’s thick and stiff, it can make it difficult to spread out. Checking the viscosity of the glue before applying/ purchasing it can save you a lot of time, effort, and money.

Cure Time

The cure time of glue is extremely important. While almost all superglue variations dry quickly, if the workpiece is used before the manufacturer’s indicated cure time it could cause the bond to break, forcing you to repeat the application process.

Always ensure the cure time of your superglue matches the time you have allocated for your project to avoid disappointment.

Strength

The strength of your superglue will determine what its limitations are. While all variations are relatively strong, if your intention is to use the glue to suspend your workpiece or hold two pieces together indefinitely, it’s best to go with a higher-strength super glue. Intensive grade and rubber-toughened superglue are often best suited for heavy-duty applications.

What Brands of Superglue Are the Best?

There are many brands of superglue out there and they all do a pretty good job, but some have a better track record than others. When it comes to tensile strength, the ability to withstand exterior forces, cure times, and versatility there are a few brands that tend to stand out based on sales and customer opinion.

Brands like Gorilla Glue, Loctite, and Scotch have some of the best track records and customer opinions out of all glues that are sold over the counter and online.

All three brands offer a wide range of high-quality adhesive products including superglue and epoxy adhesives. Choosing from any one of these brands is sure to get the job done and give you peace of mind.

Now that you know what CA glue is, how it was invented, what it is used for, and what factors to consider when choosing a CA glue for your next project, why not take your newfound knowledge and put it to the test? Remember that superglue may be versatile and strong, but some situations will require the use of stronger, more complex adhesives.

Frequently Asked Questions

Is CA Glue Super Glue?

If you have ever read the description of CA glue, you might have wondered if CA glue is a superglue. The answer to this is yes! Cyanoacrylate is what superglue is made of, and there are many variations of the substance to suit a range of everyday applications.

What Is Cyanoacrylate?

Cyanoacrylate is an acrylic monomer that is the core of superglue’s molecular composition. What is cyanoacrylate used for in superglue? It is what allows superglue to work without the need for heat or pressure, all while allowing it to dry quickly and be deployed anywhere at any time.

Is Cyanoacrylate Food Safe?

Yes! Once the glue has had a chance to dry and cure completely, it is considered food safe according to FDA ruling. If you are wondering what other types of glue are safe for food contact, two-part epoxy is also completely food safe once cured.