How to Paint Particle Board – Engineered Wood Painting Tips

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Humanity is constantly evolving, and as we evolve, so do the tools and materials we use to build the world around us. Our cars aren’t made of sheet metal anymore, we don’t send telegrams to our loved ones, and we don’t line our roofing with asbestos anymore either, all of which are good things. Construction materials have come a long way too – we don’t build brick and mortar homes as often, we use loads of plywood and resin instead of stone and concrete, and where we used to pay an arm and a leg for the solid wood board, we now use engineered woods like plywood, veneer, and even more recently, particle board. Particle board has become a pivotal part of the lives of millions of people all over the world, so let’s have a look at what it is, what it’s used for, how to paint it, and how many different types of particle board are out there.

Table of Contents

What Is Particle Board?

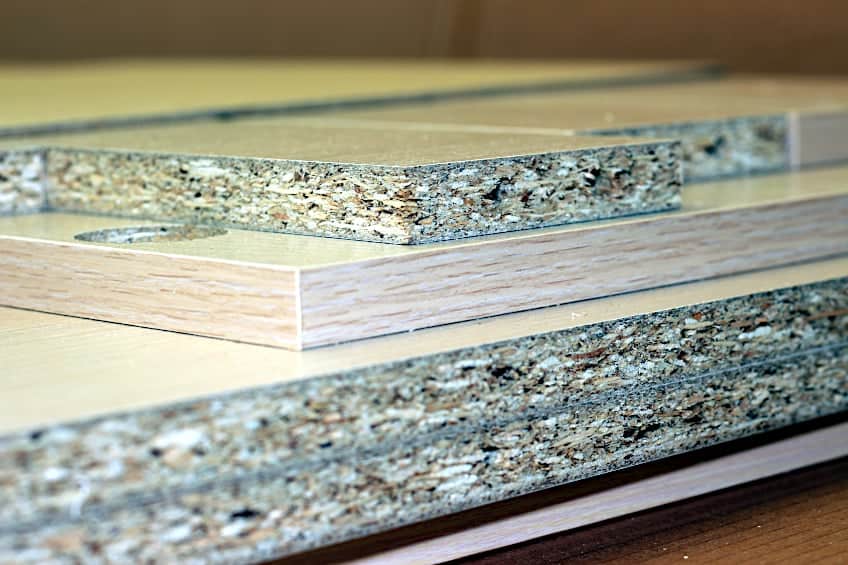

If you’re asking yourself what particle board is, it’s a sign that it’s doing its job well. Particle board is a modern substitute for a conventional wood board. What is the difference between solid wood board and particle board you ask? Well, solid wood board is (as the name suggests) solid wood that has been cut from the trunk and/or branches of a tree and shaped into various furnishings.

Particle board is also made of wood, but instead of being cut, refined, and shaped into furniture, wooden boards are constructed from pieces of shredded wood. These little fragments of wood are then mixed with an epoxy and compressed until they form the shape of a solid wood board, at which point heat is introduced to solidify the form. These little wood particles have now been compressed so densely that they have formed a solid, which is what we know as particleboard. Particle board manufacture means that every single part of a felled tree is used and nothing is wasted.

This process was first attempted in 1887 by a German manufacturer who called the new material artificial wood instead of engineered wood as it’s commonly known today. This process was later refined to use more uniform pieces of wood in the construction of particle board so less epoxy would be needed to ensure its structural integrity.

These days, particle board is used in various industries all over the world, which comes as no surprise considering that it is often a fraction of the price of conventional materials like solid wood and metal. Particle board is even made in various qualities to cater to those who need increased strength, durability, affordability, and aesthetic appeal, which makes it extremely difficult for solid wood to compete with it.

Another reason that particle board is so popular is that not only can it be made to fit your desired size and strength, but it can be made to look like any solid wood species too! How is this possible you ask? Well, once a particle board has been formed, paper-thin pieces of wood are adhered to the surface of the board, allowing the particle board to emulate the appearance of any wood species, whether it be pine, walnut, oak, cherry, or any other wood you’d like.

These sheets are known as veneer, and they have been used on many other types of engineered wood such as medium-density fiberboard (MDF), plywood, and composite board to mimic the look of solid wood and provide a stunning finish. This being said, high-quality fiberboard is cheaper, easier to work with, and more readily available, denser, and stronger than virtually any solid wood species out there.

Are There Different Types of Particle Board?

Yes! There are different types of particle board designed to meet the needs of different applications in different industries. These range from chipboard which is produced from very fine splinters of wood to oriented strand board (OSB), comprised of much larger strands or flakes of wood. Since particle board can be made as dense, as big, and/or as heavy as you’d like the possibilities are endless but based on what is needed most often manufacturers have a few types of particle board ready to go straight off the shelf so let’s have a look at them!

Single-Layer Particle Board

Single-layer particle board is the default board you’ll be given if you walk into a hardware store and as for some particle boards. This board is simple, consisting of wood filings that are all the same size to ensure uniform shape and density throughout the board. These wood filings are densely packed and are often sealed with a layer of veneer on the primary surfaces or a laminate.

The addition of the veneer and laminate makes this type of particle board resistant to the effects of moisture and/or direct contact with water, but it is not waterproof. It is for this reason that a single layer particle board is only suited for interior use, as exposure to the elements will cause this board to well, degrade, and crack over time.

Multi-Layered Particle Board

Three-layer particle board can be characterized as one tier up from the aforementioned single-layer boards. This type of particle board is pretty neat, and as the name suggests it can have up to three layers to it to improve durability, strength, and resistance to damage. The strength comes from the surface areas of the boards where the particles are much more closely compressed than the interior of the board. By layering boards, these highly compressed areas are now also present in the interior of the board.

The smaller wood particles that form the opposing surfaces of the board increase resistance to moisture, heat, impact, and abrasion. This type of particle board is a pleasure to paint and tends to last noticeably longer than single-layer boards thanks to the presence of additional resin and wood filings.

Graded-Density Particle Board

Grade- density particle board and three-layer particle board are fundamentally the same thing, but their applications tend to differ. Like three-layer particle board, a graded particle board uses thick wood filings which are sandwiched between two layers of fine wood particles which form the surfaces of the board.

Graded-density fiberboard is usually used in the construction of furnishings which are used often. Things like cabinetry, spice racks, serving trays, and anything else that will see frequent use are usually made out of this type of fiberboard thanks to its durability and longevity. This type of fiberboard can also be sealed and painted, which is always a plus.

Melamine Particle Board

Melamine particle board is something special among the particle board types. Unlike some of the others, we’ve had a look at so far. Melamine particle board is inherently water and scratch-resistant and can be purchased ready to use in a variety of finishes which aren’t limited to simple colors, but patterns and shapes much like wallpaper.

Melamine board consists of particle board which has had décor paper adhered to the surface much in the same way the veneer would be. The wood particles themselves have been bonded using a combination of melamine-urea, resin, wax emulsion, and formaldehyde to ensure that the board is sturdy and moisture-resistant.

Cement-Bonded Particle Board

Cement bonded particle board is another really special particle board type among those we have covered so far. This is a bit of a miracle material, combining magnesium-based cement with a variety of wood particles to form a material that isn’t only cheap to make but is also incredibly effective as a construction material for a variety of applications.

This particle board type consists of around 60 percent magnesium-based cement, with the other 40 percent being equal parts water and wood particles of varying sizes. This is a rather versatile and hard-wearing material that is used in the construction of walls, ceilings, flooring, and even furniture. Cement-bonded particle board is resistant to moisture, impact, abrasion, open flames, and insect infestation.

Veneered Particle Board

This one is fairly straightforward. A veneered particle board is any type of particle board that we have had a look at thus far (excluding melamine particle board) that has had a veneer coating adhered to its surfaces. A veneer is a thin layer of wood that has been adhered to the surface of engineered wood in order to have it resemble a solid wood board.

There are many types of veneer to choose from, all of which are derived directly from the wood species they are used to resemble. The price of veneer varies according to the price of the wood species it is made from. A good example is how walnut veneer will be significantly more expensive than oak or cherry wood veneer, but veneer is still far less expensive than a solid wood board.

Laminated Particle Board

Laminated particle board isn’t used nearly as often as veneered particle board, especially in everyday applications. However, it is extremely effective in its intended applications which are usually the internals of speaker systems and in the roofing of auditoriums. Laminated particle board is really strong too, and it’s easy to clean which makes it a good surface material in commercial environments.

Laminated particle board is essentially any type of particle board that has had a laminated sheet adhered to its surface. This laminate provides a great deal of protection for the particle board It’s used to cover, which is why it’s used in applications that require really robust materials. These boards also require little to no maintenance, so they’re a great long-term investment.

Common Questions Regarding Particle Board Painting

If you’ve never painted particle board before you might have a few questions about how to handle the painting process. This is pretty common considering that particle board is a bit of a grey area when it comes to resurfacing since it’s usually sold pre-finished. This is why we’ve prepared a short section detailing some of the common questions about resurfacing particle boards.

Do You Need to Sand Particle Board Before Painting It?

You might be thinking that since particle board is not solid wood board that it doesn’t need to be sanded and primed before you can start painting, but unfortunately, you’d be wrong. The purpose of sanding and priming a surface is to increase surface friction and maximize the probability of adhesion, all of which are still required when working with particle board.

If you’re using particle board to create furniture whether it be kitchen countertops, runners, or a custom workpiece of your own design, the chances are that it already has a finish like veneer, laminate, or paper backing on it. This being said, while these finishes do look great, they aren’t particularly helpful when you’re trying to paint a surface. If you do decide to paint melamine veneered particle board, you should first sand it, then use a primer designed for glazed ceramic tiles.

You will definitely need to sand and prime your particle board if it has an existing finish. If your particle board is unfinished, it could still help to sand and prime the surface to ensure that your paint not only adheres but cures and dries evenly. After all, particle board is made primarily of little wood pieces which can and will soak up any paint you apply to it if primer is not applied.

What Types of Paint Work on Particle Board?

Now that you know it’s necessary to paint particle board it’s probably a good idea for you to familiarize yourself with which paints work on particle board. Different paint types have varying results when it comes to painting on certain materials, and particle board can be a tricky surface to both prepare and paint compared to other commonly used construction materials.

So, what type of paint works on particle board? Well, Oil-based paints tend to work best on solid wood boards, so it shouldn’t be surprising that they work best on particle boards too. Lacquer-based paints work pretty well and considering that oil-based paints and lacquer-based ones are closely related this makes sense too.

However, even though acrylic-based paints work well on solid wood boards they do not work very well on particle board. However, if you’re left with no other choice, using an oil-based primer on your particle board will allow you to use acrylic and latex-based paints with significantly better results as opposed to using primers they’re usually paired with.

Particle boards aren’t really difficult to paint. All you need to ensure that you need to prepare your workpiece adequately and ensure that you have the right tools for the job. Alternatively, you could simply purchase your particle board in your desired color or order the particle board both pre-cut and pre-painted.

How to Paint Particle Board

Wondering how to paint particle board? Painting particle board is actually pretty easy, all you need to do is prepare your board adequately and ensure that you have all of the right tools for the job before you get started. This being said, let’s have a look at a few of the steps you can take to ensure that you get the best finish possible when painting your particle board.

Sand Your Particle Board

Can you sand particle board? Considering that particle board is used primarily in the construction of furniture and cabinetry, it’s best to remove all fasters and tie-downs before you start preparing your particle board for the painting process. Remove all hinges, and screws and ensure that any dust left behind underneath them is cleaned thoroughly.

Sanding particle board is a lot easier than sanding other materials. This is because particle board is lighter and less dense than hardwood species, especially the mass-produced variety, so you don’t need to use as much pressure when sanding down the surface of the board. Using 120 grit sandpaper, sand the surface of the board to remove the majority of the surface coating. Can you sand particle board with lower grit sandpaper? Yes! Although, you risk tearing up the surface of the board.

This applies whether you have a surface coating like laminate, veneer, melamine, or if you’re working with exposed particle board. The goal here is to ensure that the surface of the board is roughed up enough to receive the primer, so once you’ve satisfied with the job you’ve done sanding, ensure that you use a clean cloth, vacuum cleaner, or compressed air to remove any stray wood particles from the surface before moving on to the next step in the process.

Prime Your Particle Board

A big part of painting particle board is ensuring that it’s well primed. This ensures that the paint not only adheres to the board well, but also ensures that the tone and finish of the paint are as even as possible, which ultimately affects the finish of your workpiece. The best brush to use when applying primer to particle board is a wide, thin brush with tightly grouped bristles.

The best primer to use when painting particle board is the oil-based variety. This isn’t only because oil-based paint works best on particle board, but it’s also useful because using oil-based primer allows you to use both acrylic and latex paints without the particle board absorbing any of the paint which can really diminish the impact of your finish.

Before you apply your primer give it a good stir to ensure that any heavier particles are re-introduced into the mixture. When applying your primer, paint following the length of the board to ensure an even application of primer. Once you’re satisfied with the job you’ve done applying your primer, allow it to dry for the manufacturer’s recommended time period before moving on to the next step in the process. If you are painting particle board with a laminate or melamine finish, you will absolutely have to use an excellent primer, or your paint will chip and peel off in no time whatsoever.

Paint Your Particle Board

Before we get into how to paint particle board furniture you should know how to prepare your paint. Like primer, paint that has been sitting on a shelf for a while will need to be stirred due to heavier particles sinking to the bottom of the container over time. Once your paint is ready, dip about two-quarters of the brush into the container to get started.

When it comes to how to paint particle board furniture the best way to go about it is to paint according to the shape of your board. If you’re working with a rectangular board simply paint from one end of the board to the other, starting at one edge and working your way over to the other. If you’re working with a rectangular board simply paint following the length of the board, and if your workpiece is irregularly shaped, paint from the center outwards.

Once you’re happy with the job you’ve done applying your paint, allow it to dry for the manufacturer’s recommended time period. If you’re wondering what the best paint for particle board is, there are many options. Although, objectively speaking, the best paint for particle board in terms of finish, durability, and price is oil-based paint.

You don’t have to apply a single coat either, but before you apply additional coats of paint ensure that you have allowed your first one to dry completely or you could risk ruining your finish completely. The best environment for most paints to dry in are spaces with little to no humidity, as a space that is too hot or too cold could extend the drying time dramatically.

Can You Repair Water-Damaged Particle Board?

Conventional particle board isn’t really known for its strength, and if you’ve owned particle board for furniture for a long time the chances are that it’s taken some damage over time. The good news is that it’s pretty easy to repair particle board and once it’s been patched it can still be painted or resurfaced with things like laminate or similar finishes.

If your particle board has been damaged by water, which usually happens to cupboards located underneath sinks or in bathrooms, you can repair it by applying some wood filler to the affected area and allowing it to solidify for the manufacturer’s recommended time period. Once it’s dried completely the board and the area that has been filled can be sanded, primed, and painted.

You can use the same process to repair loose veneer chips and scratches present on the surface of your particle board. When repairing a loose veneer, the best way to go about repairing it is to re-adhere it to the surface of the particle board using contact cement, just ensure that you keep the veneer pressed against the surface of the particle board using a clamp or weight while the cement dries.

Now that you know what particle board is, what the different types of particle board available to you are, and how to paint and repair your particle board, it’s time for you to get out there and put your newfound knowledge to the test. Always remember to allow your paint to dry completely before applying another coat and to always wear hand and eye protection when working with a wood board.

Frequently Asked Questions

Can You Paint Particle Board?

Can you paint particle board? Yes! While particle board might seem far removed from the conventional wood board it is still wood on a fundamental level. This means that particle boards can be sanded, primed, and painted just like a solid wood board.

Can You Spray Paint Particle Board?

Can you spray paint particle board? You can use spray paint to paint particle board. The trick with using spray paint to paint any surface is to ensure that surface has been properly prepared. When spray painting paint particle board, the trick is to use two coats of primer and ensure that there are no loose particles on the surface of the board.

How to Paint Raw Particle Board?

Wondering how to paint raw particle board? The process of painting raw particle board is pretty much the same as painting particle board with an existing finish. You need to sand the surface, then apply your primer, and then apply your paint. Ensure that you allow your primer and each coat of paint to dry completely before applying the next.