How to Mix Epoxy – The Best Mixing Epoxy Resin Guide

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

The epoxy resin mixing is the most important step in the processing. So before you use epoxy resin for the first time, we recommend that you read through our 11 most important tips to avoid any unpleasant surprises.

Table of Contents

- The right Mixing Ratio

- Epoxy Resin Mixing by Volume Instead of Weight

- Observe Ambient Temperature

- Air Humidity During Processing

- Warm up the Epoxy Resin Before Processing

- Use Only Compatible Colors

- Careful Mixing of the Components

- The Right Tool for Epoxy Resin Mixing

- Buy Only High Quality Epoxy Products

- Mixing Different Brands or Products

- This Happens if the Mixing Ratio is not Observed

- Water and Epoxy Resin Are not Compatible

- Mixing in Sufficiently Large Containers – Attention Heat Generation

- Conclusion for Mixing Epoxy Resin

The right Mixing Ratio

Each product has a different mixing ratio. Typically, this is 1 : 1 or 2 : 1 between resin and hardener, but there are also much more complicated ones such as 100 : 45. You can usually find the details on the packaging or containers. The mixing ratio has to be very precise, otherwise the epoxy resin will not harden or it will not work optimally. Our epoxy resin calculator will help you with the calculation.

Epoxy Resin Mixing by Volume Instead of Weight

The density of resin and hardener may differ. Therefore the weight is not identical either. If you now measure resin and hardener 1 : 1 by weight with a scale, the mixing ratio is not correct, because resin and hardener have different weights. The more volume you mix, the bigger the problem.

Therefore our tip: Mix by volume with a measuring cup. In this way, the density of the materials is not important.

Use a measuring cup with a sufficiently fine scale so that you can measure exactly. After pouring in the epoxy resin, wait a short time until the surface levels out. Then mix in the exact amount of hardener.

Observe Ambient Temperature

Epoxy resin reacts sensitively to temperatures. This is very important to know, as heat is a very important factor for the success of your project:

- Temperatures below 20 degrees / 68F: The curing of the resin slows down considerably. In addition, more amine reddening may occur (waxy layer), which must first be laboriously removed before further processing. the resin may also crystallise at too low temperatures.

- Temperatures higher than 20 degrees / 68F: The resin-hardener mixture will react faster at temperatures above 20 degrees Celsius. This reduces the pot life as well as the time until complete curing. In this case, a product with a longer working time should be chosen.

Even when used outdoors, curing can slow down considerably if the temperature drops during the night. In addition, dew can reduce the quality of the surface due to the temperature differences.

Air Humidity During Processing

Hardeners react relatively sensitively on contact with air. Therefore, do not open the bottle with the hardener at air humidity above 65%, as the hardener will already suffer qualitatively if not used up immediately. The more you open the hardener container, the more oxygen is added and the worse the result will be.

If you take out Resin and hardener out of your container or bin, it should be done with a clean tool so that no reactions take place in the container.

Tipp: Make sure that the air humidity remains below 70% during epoxy resin processing, as undesirable effects can occur here as well.

If the substrate has more than 6% humidity (e.g. a concrete floor or other materials), we recommend the use of a primer.

Warm up the Epoxy Resin Before Processing

Before using epoxy resin, it should be stored for 12 hours at a temperature of 20 to 25 degrees Celsius for optimal properties. A warm water bath can also bring the resin to the required temperature if it is in a hurry. If the epoxy is too cold, milky streaks or bubbles may appear which are difficult to remove.

Heating the mixture improves the flow properties, but reduces the open time. As a rule of thumb it can be said that an increase of 10 degrees Celsius halves the pot life and curing time.

Tip: Also note the surface temperature: If you use an epoxy resin with a temperature of 20 degrees, but pour it onto a much colder surface, the temperature will be too low and curing may be impaired. For best results, keep the temperature and humidity constant.

Use Only Compatible Colors

Not all colours are compatible with epoxy resin. When colouring with epoxy resin, it is therefore important to use only suitable colour pastes, colouring agents and pigments. You can find more information in our guide article Epoxy resin color.

Careful Mixing of the Components

The mixing of resin and hardener must be done very thoroughly. If you mix the two components too little, you may get locally sticky, incompletely cured areas or different degrees of hardness of the material.

Do not mix too small quantities of resin and hardener, as the adhesion to the edge of the container causes a comparatively large amount of material to adhere, which means that the mixing ratio is not optimal.

The Right Tool for Epoxy Resin Mixing

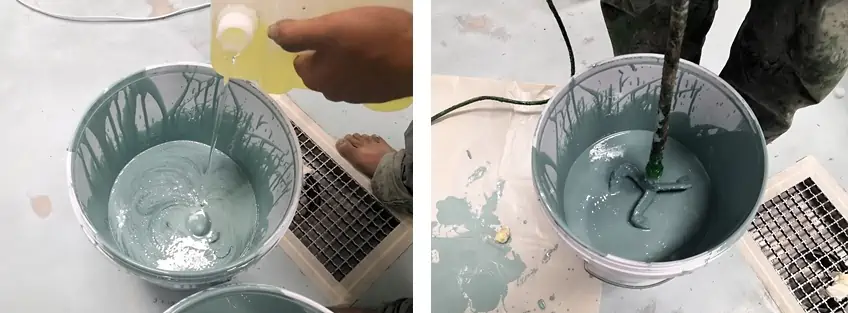

Mixing big amounts of Epoxy resin

The best tool for mixing epoxy resin is a flat spatula, similar to a paint stirrer. The cheaper variant is a wooden spatula, but it is only available in small sizes for smaller quantities. For medium quantities, there are special epoxy resin mixing sticks, which are designed to prevent too much air from being stirred in and can be used several times. The sides of the mixing tool must be straight so that the material adhering to the sides and bottom is also mixed thoroughly.

Tip: A bucket with a spout is recommended for larger quantities. You can then mix the epoxy resin in a time-saving manner using a drill with a stirrer.

Buy Only High Quality Epoxy Products

There is a whole range of cheap products, which either do not harden or are already yellowish when ordered. It is therefore worthwhile to buy high-quality epoxy resin.

Mixing Different Brands or Products

Epoxy resin and hardener are specially adjusted to each other in all products. Therefore, different products – even those of the same manufacturer or even different brands – must not be mixed with each other. This can lead to unforeseen chemical reactions, such as extreme heat development.

This Happens if the Mixing Ratio is not Observed

If you add more hardener than specified, the cured material will become poor in its properties, for example, less hard and resistant. Conversely, too much resin is responsible for the fact that the hardening may even stop completely and the surface will always remain sticky.

Bilder: Little honey / shutterstock.com

Water and Epoxy Resin Are not Compatible

Water or moisture and synthetic resin are not friends – at least in a liquid state. Mixing equipment such as spatulas and containers for epoxy resin mixing must be clean and free of moisture. Even a small amount of moisture can have a significant negative effect on the properties of the end product.

Mixing in Sufficiently Large Containers – Attention Heat Generation

When mixing epoxy resins, an exothermic reaction is created by the compound. The mixture heats up, depending on the resin, the quantity mixed and the height of the vessel. It is important to note:

- There is an upper limit for the maximum amount of resin and hardener that should not be exceeded (check with the manufacturer). In case of doubt, it is better to mix twice.

- Mix in sufficiently large containers, which should be wide rather than high. This reduces the heat build-up.

- For large quantities, use low-reactivity epoxy resins that generate less heat.

Conclusion for Mixing Epoxy Resin

Actually, it sounds quite simple: Just mix components A and B together and the job is done. The devil is in the details, however, and there are a few factors such as ambient/surface temperature and humidity and other points to consider in order not to waste the relatively expensive epoxy resin. If you take the individual points to heart during processing, you are much more likely to get a result according to your expectations.

Good Luck with your Next Epoxy Resin Project!