How to Glue HDPE – Finding and Using the Best HDPE Adhesive

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Despite its versatility as a plastic produced for a useful range of purposes, HDPE poses the challenge of being very difficult to glue. Parts are usually welded together using various processes limited to industrial settings. However, thanks to developments in the adhesive industry, some epoxy glues are now available that make gluing HDPE surfaces together almost seamless. If you are wondering how to glue HDPE, and what products to look out for, keep reading the indispensable information provided in this tutorial.

Table of Contents

Introduction to Different Types of Plastics

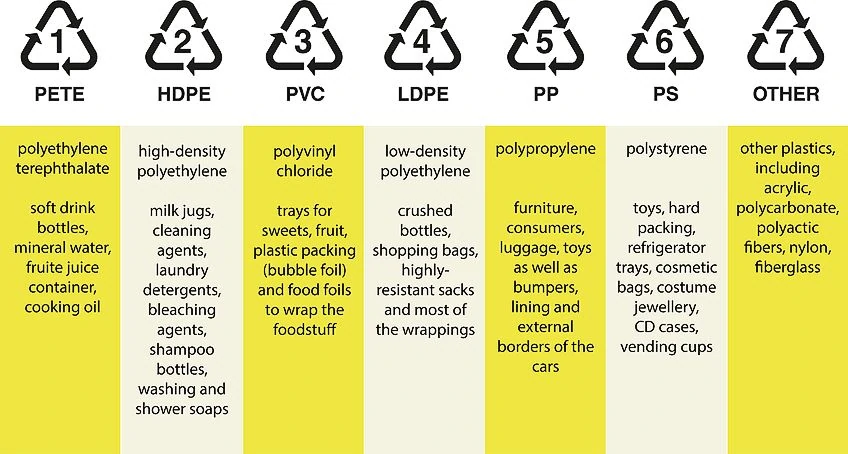

Love them or hate them, plastics are an essential and unavoidable part of our everyday lives. As you may know from reading the packaging of various things you buy, there are seven different types of plastic, each with its own properties:

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PETE or PET)

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

- Polystyrene (PS)

- Low-Density Polyethylene (LDPE)

- Other (including fiberglass, acrylic, and nylon)

How you glue plastic depends on the type of plastic you want to glue. A couple of years ago, most experts would have told you that gluing two pieces of HDPE together, or even HDPE to any other surface, was improbable with the technology available at the time. These days, however, gluing HDPE does not have to be an impossible task because an HDPE adhesive is not hard to find. This is also a hard topic to resist exploring because HDPE takes decades to decompose, so it is always better to reuse and recycle the plastic into a wide range of different things.

What Is HDPE?

Polyethylene (PE) is one of the most widely produced and commonly used plastics today. It is a thermoplastic polymer, which means that when heated to its melting point, it melts without losing its structure instead of burning, as other plastics do.

Polyethylene comes in three different forms: low-density polyethylene (LDPE) and high-density polyethylene (HDPE), as well as ultra-high molecular weight polyethylene (UHMW). LDPE is used for things like medical equipment, packaging, and insulation for cable wires while HDPE is commonly used for bottles such as shampoo containers and detergents, as well as other soaps and cleaning agents.

The benefits of this particular type of plastic are that it is light, durable, strong, flexible, and immune to corrosion. It is also cheap to make when compared to other materials, making it the go-to solution for many modern-day packaging needs.

Before we move on to understand more about the chemical processes that occur during HDPE bonding, and how you can bond pieces of this plastic together, you may be interested to know a little about the origin of this plastic.

Polyethylene first made an appearance in the history of chemistry in 1898, when it was created by accident in a laboratory by a chemist called Hans von Pechmann. A later variation of polypropylene, HDPE was invented by Karl Ziegler and Erhard Holzkamp in 1953, and it was only two years after its invention that the first HDPE pipe was produced. Ziegler won the Nobel prize in 1963 for this invention.

Bonding HDPE

HDPE is notorious for being a difficult plastic to glue because of its “high abrasion resistance”. This refers to its hard surface or low surface energy, which often makes regular glues and superglues ineffective. Polyethylene can be bonded through welding or using nails, screws, or specialized glues. Unless you are wanting to create a particularly industrial-looking effect, nails and screws are not the most subtle option for joining two pieces of plastic together, even though it is an age-old and highly effective way of fixing two stubborn surfaces together.

In contrast to the not-so-subtle method of the hammer-and-nail method, welding is the bonding of plastics on a molecular level, resulting in a strong, invisible bond that retains the properties of the plastics being joined. You can melt the surfaces you want to bond through heat or by using corona or plasma treatment of the plastic.

Note that welding only works for joining two pieces of HDPE together and cannot be used for gluing HDPE to other types of plastic or other materials such as wood or metal. Flame, plasma, and corona treatment of surfaces usually take place in industrial settings as they require specific and expensive equipment that is inappropriate in the home context. Additionally, welding generally occurs for production on a much larger scale than the gluing needs of individuals in their everyday lives.

However, this is not to say that gluing HDPE is beyond the realm of possibility for you. If you find yourself with HDPE at hand, and you need to glue it to another piece of HDPE plastic or other materials, you do have a few options at your disposal. As you peruse the shelves of your regular hardware store, you may find that many superglue varieties claim to be suitable for plastic. However, many of them will be useless when gluing HDPE as they tend to form beads on these surfaces instead of sinking into them, so do not be fooled.

For this reason, we would like to emphasize that you do thorough research before choosing your glue. The available options include some superglues (which sometimes need to be combined with other substances) and certain HDPE epoxy glues.

Recommended Products

As we have seen, HDPE gluing can be a challenging business, and getting your hands on the right product is one of the most important parts of the process. If you want to glue HDPE parts together, there are several products on the market that can cater to you, although some are better at delivering on their promises than others. This is why we have come up with a list of products that we think you will love.

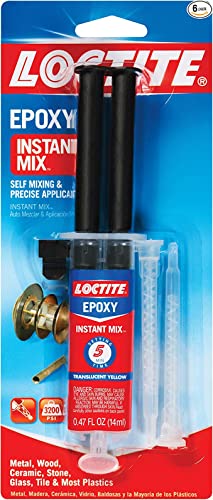

Best for Quick Repairs: LOCTITE Epoxy Five-Minute Instant Mix

Loctite’s Epoxy Five-Minute Instant Mix makes it onto our top-three list because it takes the “hard” out of “hard work”. This product includes a mixing nozzle that allows for the consistent mixing of hardener and resin, making the gluing far easier than products that require you to mix by hand.

It is resistant to water and shrinkage and is suitable for smaller projects – the tube contains 14 ml of glue, which is negligible when compared to industrial-strength glues that come in much larger quantities. The product has a narrow nozzle that can get into hard-to-reach places that heavy-duty products are not able to access. Reasons to buy it? Reasons not to? See the pros and cons list below.

- Easy-to-use self-mixing dispenser and precision applicator

- High-strength formula bonds wood, metal, plastic, glass, and more

- Waterproof, sandable, paintable, and will not shrink

PROS

- User-friendly

- Can be sanded and drilled

- Paintable

- Quick-drying

- Suitable for bonding many types of hard plastics, among many other materials such as concrete, glass, and metal

- Waterproof

- Color can be changed by adding pigments, sand, or cement

CONS

- Not suitable for larger projects

- Unpleasant smell

- Cannot be used in extreme temperatures

Best for Larger Projects: J-B WELD Professional Steel-Reinforced Epoxy Twin Pack

One of the most popular products on Amazon, J-B Weld’s Professional Steel-Reinforced Epoxy delivers in terms of unmatched strength and versatility. In contrast to the previous review, this product comes in quantities that are more appropriate for larger projects such as household, outdoor, and craft repairs.

This epoxy glue promises to provide a bond that is stronger than steel, and it is. It takes a little longer to dry than other brands (4-6 hours) and takes up to 24 hours to cure fully, but it is worth the wait! Once dry, the glue has a dark gray finish.

Like other epoxy glues, this product can be drilled, sanded, and filled. It is weather-proof and resistant to acid and other chemicals, making it the best glue for HDPE. See below for more details about the advantages and disadvantages of using this product.

- A steel-strength bond formulated as an alternative to torch welding

- Can be tapped, filled, sanded, molded, and drilled once cured

- Waterproof and resistant to petroleum, chemicals, and acid

PROS

- Strong bond

- Suitable for use outdoors

- Can be sanded and drilled

- Resistant to high temperatures and water

CONS

Best for Heavy-Duty Use: LOCTITE Heavy-Duty Five-Minute Epoxy

Loctite’s Heavy-Duty Epoxy gets the job done, and gets it done fast. If you want a no-nonsense, quick-drying, heavy-duty epoxy, look no further than this affordable product. We have included this glue in our list because it is effective for heavy-duty use as well as for projects that require successive gluing.

Examples of projects in which this glue will provide a solid bond are fencing, laminating, and stonework. It not only works on a variety of hard plastics but also on metal, wood, ceramics, tiles, and fiberglass, in addition to other materials. Overall, this is a good glue to have around. Here are some of the pros and cons that you can expect to experience when using this glue.

- For use on large or multi-piece jobs requiring a high bond strength

- Resistant to water, high impact (including drilling), and shrinkage

- Can be combined with fiberglass cloth for a durable patch

PROS

- Dries in five minutes

- Heavy-duty bonding

- Good resistance to impact

- Water-resistant

- Can be sanded

- Not susceptible to cracking when drilled

- Does not shrink

CONS

- Not suitable for smaller projects

- Poor shelf life

- Pungent smell

How to Glue HDPE

Whether you are using epoxy glue or super glue, most glue types will require you to prepare the surfaces you need to stick together before you can apply them. What this usually requires is the sanding of both surfaces (especially if you are gluing two pieces of HDPE together), and then vacuuming the dust particles away so that the surfaces are completely clean. Any residual dirt will inhibit adhesion.

Once this has been done, you will need to glue your plastics together by following the precise instructions given on the product you are using. Instructions vary according to the brand you are using. HDPE epoxy glue, or any epoxy glue, will require you to mix a hardener with a resin, which will either be done by hand (by you), or the glue will come in two compartments that can be applied at the same time.

Once the HDPE epoxy glue has been mixed propely, apply it to one surface and clamp the two surfaces together until the glue has finished drying and curing.

If you are using superglue, even the best glue for HDPE might require you to use a primer in addition to the glue, without which the superglue will not work. You would apply this primer to the plastic and wait for it to dry and cure properly before you apply the glue. The drying time of any kind of glue you are using will be indicated on the packaging.

Precautions

Using HDPE glue can be hazardous and, if you do not prepare properly before the gluing process begins, expensive. Here is a list of precautions to take and preparations to make before you start in order to ensure that your gluing process is painless, hassle-free, and free from mistakes.

- Make sure that the area you are working in is well-lit and well-ventilated. Alternatively, you can work outdoors.

- Gather everything you will need before you start gluing to ensure that you do not have to interrupt the process once you have begun.

- When buying glue, opt for one that is clear – this will prevent the appearance of unwanted seams if the glue oozes out from applying too much.

- You can prevent oozing by applying the recommended amount of glue.

- Use your glue with caution so as to avoid spilling any on your body and other surfaces. It is difficult to remove once it has dried, and glues are sometimes quick-drying.

- Choose a flat surface to work on.

One of the most commonly used plastics today, HDPE is used in the making of a wide range of products due to its lightweight quality, flexibility, and strength. A highly durable plastic, it is often re-used for creative and DIY projects. Once difficult to stick together, HDPE is no longer an untouchable plastic thanks to several affordable products that are available online. Buy the correct glue and follow the instructions provided on the packaging, and you will have your HDPE glued together in no time!

Frequently Asked Questions

Can You Glue HDPE Together?

Although this type of plastic is notorious for being difficult to glue, the answer is yes, you can glue HDPE parts together. Previously, this could only be done by welding pieces or nailing/screwing them together, but today various types of glue are available for bonding this plastic, including epoxy glues and selected superglues. With the correct surface preparation and glue, you will be able to ensure that your HDPE sticks together well and with virtually no visible seam.

Will Superglue Work on HDPE?

Yes, some types of superglue will be effective in the HDPE gluing process. You should, however, be aware that not all superglues will work on this type of plastic. Even if the packaging states that it works on plastics, this may exclude HDPE, so do some research before you buy your glue to ensure that you will have success. Also, note that some brands require you to use a primer before applying the superglue. Alternatively, you can use some epoxy glue brands instead.

How Do You Glue HDPE Panels Together?

Most brands of glue require surface preparation before you glue pieces of plastic together. This entails the sanding of both surfaces and vacuuming the remnant dust off. Instructions on how to apply the glue will vary from brand to brand, so make sure that you read the instructions on the packaging before proceeding. Once you have applied the glue to one or both surfaces, you may need to clamp your pieces of plastic together to allow them to dry and cure. If you use HDPE epoxy glue, part of the preparation will involve mixing the hardener and the resin.

Can You Bond HDPE?

HDPE is a hard plastic with low surface energy, making it extremely difficult for glues to stick to these surfaces. But yes, HDPE can be bonded either by welding pieces together or by using an appropriate superglue or epoxy-based HDPE adhesive and perhaps a primer, thanks to developments in the glues that are available. Make sure that you buy the correct glue and read its usage instructions carefully before attempting to bond your pieces of plastic together in order to ensure guaranteed success.

What Glue Works on HDPE?

Some brands of epoxy glues work well for gluing this notoriously difficult-to-glue plastic, such as those produced by the Loctite and J-B Weld brands. Other products that might work include certain superglues, but these must be combined with other substances such as a primer to be effective. Be careful to ensure that the superglue you use is suitable for gluing hard plastics, as many types of glue that claim to be effective with plastics are not referring to HDPE specifically.