Brad Nailer vs. Finish Nailer – Which Nail Gun Type to Choose

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

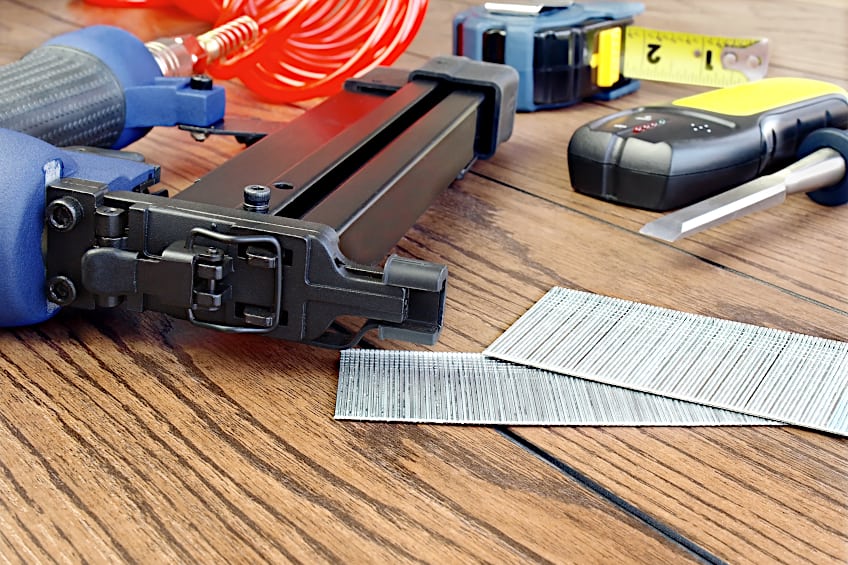

Nail guns are used for many things, from securing baseboards to holding trim in place. You may have heard the terms “brad nailer” and “finish nailer” before, and they are often used interchangeably. However, these tools, although visually similar, are not the same. That being said, let’s have a look at the brad nailer vs. finish nailer debate, establish what they are respectively, and what their intended applications are in the home improvement and crafting worlds.

Brad Nailer vs. Finish Nailer: What Is the Difference?

Before we get into the finer details let’s establish what a brad nailer and finish nailer area respectively. While the terms are often used interchangeably by the uninitiated due to them being visually similar, there are key differences that establish each tool as unique. Let’s have a look at the difference between these nailers so you don’t get them mixed up.

Finish Nailer

A finish or finishing nailer, as the name suggests, is designed to apply the final finishes to a construction job. Finish nailers dispense high-caliber nails that are used to secure thick materials such as dense solid wood and even plastics at times. They are also commonly used for installing hardwood flooring. Finish nailers dispense nails between 14, 15, and 16 gauge. To put this into context, the smaller the number the thicker the diameter of the nail.

The length of the nails that finish nailers are capable of dispensing can be anywhere between half an inch and around 3 ½ inches in length. As you can see, these are long, stubby nails that are designed to penetrate the surface of a workpiece and firmly secure it to the substrate or other bits of material. This is very much a “heavy-duty” tool designed for bigger projects.

As you can imagine, dispensing nails of this size requires a lot of force. This makes the finish nailer the stronger option, with strength and nail size being the defining difference between brad nailer and finish nailer units, at least from the perspective of a finish nailer user. With that being said, this makes the finish nailer far heavier and more robust.

Finish nailers would be used in applications where heavy-duty nails are needed. A good example of this is when arms need to be attached to chairs when joins are not present. Large trim pieces above archways or doorways may also require the use of a finish nailer due to smaller nails not being able to support the overall weight of the workpiece.

- Thicker nails can be driven through harder surfaces

- Most allow you to adjust the depth to which the nail sinks

- No need to countersink finish nails

- Capable of driving through a wide variety of materials

- Robust design

- Capable of suspending heavy workpieces with ease

- Capable of dispensing a variety of large nail sizes

- Can be very heavy

- Robust design can make them challenging to handle

- Cannot be used on thin materials as they could split

- Tend to require the use of compressed air via a compressor or turbine

- Nail holes are far more noticeable when compared to brad nails

- Tends to be far more expensive than brad nailers

- More likely to split rigid materials on contact due to the diameter of nails

Tips for Using a Finish Nailer Effectively

While finish nailers are fairly simple to use you should ensure that you know exactly what to do when attempting to operate one. Nailers have safeguards in place to ensure they don’t go off accidentally so you don’t have to worry too much about accidentally piercing yourself or something around you, but generally, you should follow an operating procedure.

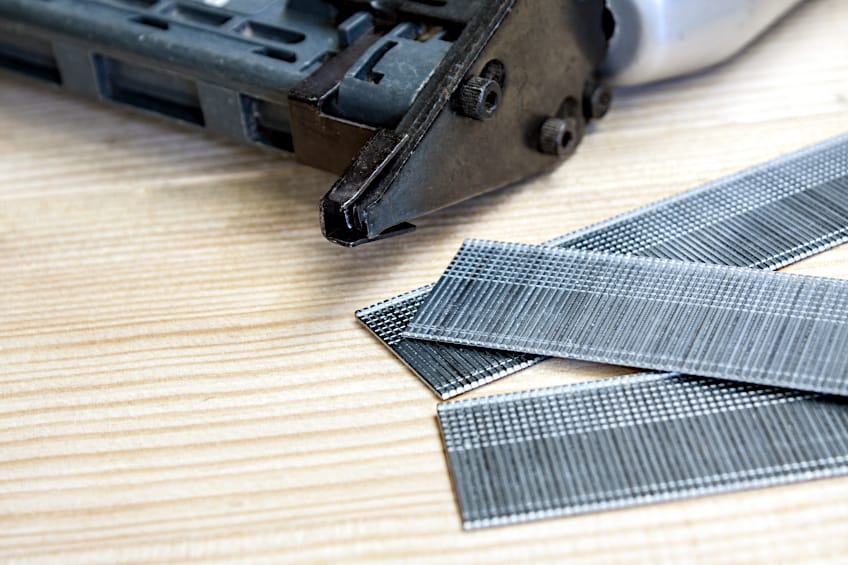

The first thing you should do is ensure that the nailer has been loaded correctly. This means ensuring that the correct size nails have been inserted into the magazine. Failing to do so can result in the nailer jamming up. This can happen even if it seems like the nail size you have chosen will fit, so it’s best not to take any chances.

Once your nailer has been loaded be sure to set the depth control. This essentially determines how far the nail will be driven into your workpiece. Setting the depth can mean the difference between successfully dispensing your nail and cracking your workpiece, so pay close attention to this setting and the tolerances of your workpiece.

When your nails have been loaded and your depth has been set, you should test your setup on some spare material before tackling your actual workpiece. Why? Finer adjustments may need to be made to your nailer, and this will allow you to test whether your nailer is functioning as intended instead of having to find out on your actual workpiece.

Brad Nailer

What is a brad nailer? Brad nailers might seem like the bigger nailer due to the name, but in reality, brad nailers dispense smaller nails than finish nailers, which is the primary difference between brad nailer and finish nailer units. How much smaller, you ask? Brad nailers can be loaded with 18-gauge nails that are usually about 2 ½ inches in length. As you can see these are thinner and shorter than finish nails by quite a bit.

These nails are not quite as robust as those dispensed by a finish nailer, but this is because their intended application is different. Brad nailers are used to dispense these thin short nails for applications such as securing trim, building small birdhouses, and even small pieces of furniture. These nails are ideal as they aren’t easy to see, to begin with, and they can be easily filled and painted over.

Brad nailers are smaller and lighter than their finish nailer counterparts. This is due to them taking smaller nails, and since there is less material to manage, it makes them easier to move around and hold steady. Brad nailers are a staple in environments where furniture is mass-produced and assembled.

What is a brad nailer used for? These are more common among DIY enthusiasts who tend to use them quite regularly for crafting applications. The learning curve regarding the use of a brad nailer might be less steep considering that it would be pretty challenging to crack or split wood when using one, but you could damage your nailer if you attempt to use a brad nailer on very dense and/or thick materials.

- Are relatively inexpensive when compared to finish nailers

- Much lighter when compared to finish nailers

- Not likely to crack your workpiece when used

- Can generally be found in pneumatic and electric variations

- Can be used to firmly secure lightweight trim and similar objects

- Ideal for DIY crafting applications

- Depth of penetration can be easily adjusted

- Cannot be used to secure heavier workpieces

- Nails will bend and jam dispensing mechanism if used on dense materials

- Usually requires the use of compressed air

- Can be challenging to use on materials aside from wood

- Don’t provide the same holding strength as finish nails

- Cannot be used on heavy-duty applications

Tips for Using a Brad Nailer Effectively

Operating a brad nailer is fairly straightforward. However, there are some things you can use to ensure that your workpiece is well secured. For one, you can ensure that your nailer has been loaded correctly. Brad nails are sold in strips that are fed into the magazine of the nailer, at which point they can be dispensed in sequence. It’s best not to load brad nails individually to ensure the nailer does not jam.

You should also ensure that the depth setting has been accurately calibrated. Failing to do so can result in your nails being plunged too deep into your workpiece or not deep enough. If you find yourself in either of these situations, it’s likely that the existing nail will need to be removed and another one dispensed in its place.

Most brad nailers are pneumatically powered. This means that they use either an air compressor or turbine to create the pressure needed to drive nails into a workpiece. Ensuring that you have an adequate supply of air to dispense said nails with sufficient force is important, or you could end up ruining the surface of your workpiece and/or potentially damaging your nail gun.

You should also ensure that you have the correct nail size for your gun. Never attempt to use finish nails in your brad nailer. Even if they seem able to fit in your brad nailer, it does not have sufficient force to drive nails of that size. Remember, brad nailers use 16-gauge nails exclusively and anything larger than that likely will not work or damage your tool.

Brad Nailer vs. Finish Nailer Comparison

Now that you know what these nailers are and what their intended purposes are, we thought we’d compare them so you can see which is best suited to a particular application. Remember that while brad nailers are less robust, if used in sufficient numbers brad nails can secure many heavier workpieces. Finish nailers on the other hand tend to damage workpieces that are too small or brittle.

How Do They Compare to One Another?

There cannot be a direct comparison between these two nailer types. Why? Put simply, they are intended for different applications and therefore it wouldn’t be fair to judge one based on the intended use of the other. Brad nailers are designed for light work, primarily securing lightweight workpieces, crafting, installing wall and ceiling trim, and securing signage.

Finish nailers have been designed for heavy-duty construction applications. This includes securing baseboards, installing window and door frames, and even things like crown molding. Finish nailers dispense larger nails and are therefore bulkier and a bit trickier to manage when compared to brad nailers. However, this appears to be a worthwhile tradeoff considering what one is able to accomplish.

Brad nailers are a lot lighter and easier to flick around as needed, especially in confined spaces. However, they aren’t as versatile and dispense a smaller caliber of nail. This means that they are incapable of being used in construction applications as they cannot hold up larger workpieces. That being said, they don’t crack surfaces the way finish nailers tend to.

Does this mean that one is better than the other? Absolutely not. When using a brad nailer, you forfeit power and caliber for maneuverability and ease of use. When using a finish nailer you forfeit ease of use, discretion of your nails, and maneuverability for power and superior fastening strength. Whether these compromises are worth it depends entirely on what you are trying to accomplish.

The ideal scenario when it comes to the brad and finish nailer is to have both on hand. You would have your finish nailer to secure larger workpieces with more power and not risk them falling off. When working with smaller workpieces you would have your brad nailer to secure them and not risk them splitting in half. As you can see, the value of each is entirely dependent on the application.

Factors to Consider When Choosing Between a Brad Nailer and Finish Nailer

If you have not used a nailer before it can be challenging to decide which one you need for your project. Thankfully, there are a few questions you can ask yourself to determine whether you have the right nailer for the job. To make things a bit easier for you we have listed some of the questions you can ask yourself below.

How Heavy Is Your Workpiece?

As we mentioned previously, finish nailers dispense thicker, longer nails designed to hold up really heavy objects. However, attempting to use a finish nailer on thinner, more brittle material can result in it cracking your workpiece.

The inverse is something you should consider as well, as attempting to use a brad nailer to hold up a heavy object simply won’t work in most cases.

How Dense Is Your Workpiece?

Weight and density are often associated with one another, but an object can be dense and still be relatively light. For example, you might be tempted to use a brad nailer on a small object even though it is made of really dense material.

Brad nailers are not very good at penetrating dense material, so the better option would be to use a finish nailer instead.

What Will Your Workpiece Be Used For?

You should also understand the forces your workpiece will be subjected to. Even if you manage to suspend a heavy object using a brad nailer, the nails might not be able to handle the weight for a prolonged period of time.

The inverse could also be the case, where lighter workpieces need to be secured with a stronger finish nail due to pushing, pulling, or torsion forces acting on them. Always consider what forces will be acting on your workpiece when choosing a nailer.

What Makes Sense Aesthetically?

The intended purpose of your workpiece might not be a practical one, in which case you should consider the aesthetic impact of the type of nail that will secure it. Trim pieces and molding are usually secured using brad nails because they are thinner, can be driven in deep, and the heads are easy to cover up (if they’re noticeable at all).

Finish nails on the other hand are used in applications where aesthetics isn’t the number one concern.

Finish nails are typically used for functional applications because they can take considerable effort to cover and/or integrate into the workpiece, so knowing which nail type would best suit your workpiece in its intended application can save you a lot of time, money, and effort down the line.

What Is Your Nailer Capable Of?

Brad nailers will usually jam up if you try and use them on workpieces that are too hard or too dense. Finish nailers will crack a material that is too brittle for the caliber of nails they use.

Understanding the limitations of the caliber of nails your tool dispenses and what effect using them on certain materials will have is also very important.

Do You Have the Right Nails for Your Nailer?

Brad nailers typically dispense 18-gauge nails only. You might be tempted to use a 16-gauge or 17-gauge nail in it, and if you do, simply don’t. Using the incorrect nail size in your nailer can result in the tool jamming, which can be costly to repair if the damage is extensive. The same goes for using smaller nails in a finish nailer, as the force applied to them would be excessive.

What Powers Your Nailer?

While it’s easy to get swept up in what your nailer is capable of doing, it’s easy to forget that you will need to power it somehow. There are two types of nailers, ones that are powered by compressed air (pneumatic) and ones that are airless (electrical). Nailers that are powered by airlines require you to have a compressor or turbine, but they are the cheapest of the two variations.

Nailers that are powered by electricity are known as cordless nailers. These contain battery packs that need to be charged between uses and allow you to move around unrestricted by an air line. With that being said, cordless nailers are far more expensive, contain far more components that could break, and are far heavier than pneumatic ones.

When to Use Each Nailer

Having all the factors you should consider when choosing a nailer only solves half the problem. You will need to familiarize yourself with when each nailer is applicable and why. Using your nailer on a project that isn’t compatible with the type of nails it dispenses can be disastrous, so here are a few common projects nailers are used for and which nailer type is best suited for them.

Securing Wall Trim

When securing wall trim, one of the quickest ways to ensure that it doesn’t move anywhere while the adhesive dries, or to lock it in place permanently, is to make use of a nailer. Arguably the best type of nailer to use for this application is the brad nailer. Why, you ask? Brand nails are thin and pretty challenging to see, and if they are visible, they can be hidden pretty easily.

Finish nailers would be an objectively poor choice for commonly used wall trim unless you are installing uncommonly thick trim. Because the wood species trim and corner rounds are usually made of, the likelihood of you cracking the trim due to the size of finish nails and the power with which they’re driven in is very high.

Upholstering and Furniture Assembly

When assembling furniture, especially by hand, one of the fastest ways to ensure that smaller parts are secure is by using a nailer. Usually, brad nailers are used as they are easier to manipulate and don’t leave gaping holes in the wood when inserted. This ensures these holes can be filled, sanded, and resurfaced if the frame of the furniture will be visible.

However, finish nailers can also be used in the creation of furniture. If you were making a thick bedframe or a large sofa set, brad nails would be a good choice. Solid wood furnishings made of particularly dense wood species would likely reject brad nails causing the nailer to jam up, which can be frustrating to correct.

Construction and Home Renovations

Home renovations can be stressful and time-consuming, especially if you are doing them on your own. Thankfully, nailers can make things a lot easier for you if you know where and how to use them correctly. For example, attaching the trim to and accents to kitchen cupboard doors can easily be done with a brad nailer. If you have heavy trim pieces like ones that frame doorways, you’re going to need something a bit more robust, which is where the finish nailer comes into play.

Finish nailers can also be used to secure support beams of objects that aren’t integral to the structure of the buildings like porch covers and curtain rail covers. For anything else, you will need a larger caliber nail gun.

Now you know exactly what finish nailers and brad nailers are. Knowing which one is used for certain applications can save you from purchasing and/or using the wrong one for your next project, but don’t forget to assess the materials you’ll be using them on too. Remember that even a good tool can yield poor results if used incorrectly, so do your research beforehand to avoid disappointment.

Frequently Asked Questions

What Is A Finish Nailer Used For?

If you’ve never used a nailer before, you might be wondering what finish nailers are. What are finish nailers, then? Essentially, finish nailers are large nail guns that dispense 15-gauge nails These are thick and stocky nails that are designed to secure heavy workpieces.

Is a Brad Nailer the Same As a Finish Nailer but Smaller?

Brad nailers dispense smaller, thinner nails compared to finish nailers. Is a brad nailer the same as finish nailer but smaller then? Not really, as brad nailers and finish nailers are roughly similar in size, with the main difference being that brad nailers are designed to hold and dispense smaller nails. This means that brad nailers can be designed smaller, which saves on materials, production cost, and weight.

What Is a Brad Nailer Used For?

Brad nailers are often seen in DIY video tutorials, but what is a brad nailer used for? The intended purpose of a brad nailer is to dispense small, thin nails that are meant to discreetly secure lightweight materials to another surface or object.