Best Glue for ABS Plastic – The ABS Adhesive Guide for Durable Joints

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

ABS is one of the most commonly used everyday plastics today. ABS enjoys great popularity not only in household and sanitary applications, but also in the hobby sector. However, this also brings problems, because it is difficult to glue ABS or repair it with the help of glue. Find out why this is so and how you can still manage to glue ABS plastic in our guide.

Table of Contents

What Is ABS Plastic?

ABS is short for acrylonitrile butadiene styrene. This is a plastic that has become an indispensable part of our everyday lives thanks to its extremely positive material properties. It is used not only as housing for a wide variety of electronic devices, but also for household goods and for pipe sheathing in the sanitary sector.

ABS can be perfectly coated with metals by electroplating. Printing and overpainting are also no problem. Chrome plating of ABS plastic surfaces is now standard practice, especially for household and electrical items, such as coffee and espresso machines.

Despite all the positive material properties, however, ABS has one serious disadvantage: it is very difficult to bond this type of plastic.

Properties of ABS Plastic

In its basic form, the ABS thermoplastic is colorless to gray; in some cases it also has a yellowish tint. This plastic is popular in industry as well as in the hobby sector because it has very positive properties:

- Very good heat resistance

- High resistance to weather-related influences

- Good chemical resistance (especially to mineral oils, greases, alkalis, and undiluted acids)

- Very high scratch resistance

- High aging resistance

- Good mechanical properties: high surface hardness and impact strength

A major disadvantage, however, is the fact that ABS is a low-energy material. This means that the surface energy is too low to develop good adhesive properties, which makes gluing ABS plastic very difficult.

In order to achieve a good adhesive effect, the choice of the right ABS adhesive is crucial on the one hand, but also optimal surface preparation on the other. You can find out which are the best adhesives for ABS below.

The Best Glue for ABS Plastic

To glue ABS plastic, it is not enough to take any adhesive and join the substrates together. As a rule, this does not achieve the desired effect, but only ensures extremely unsightly glued seams that break or fall apart even under a light load. In the worst case, this ruins an expensive workpiece. Therefore, it is better to use the ABS adhesives that we have presented.

Epoxy Resin ABS Adhesive

Epoxy resin adhesive is a two-component adhesive that works on the basis of a chemical reaction by mixing resin and a hardener. Such adhesives form extremely strong bonds. Bonding different materials such as metal and wood is also no problem. Epoxy resin adhesives are particularly suitable for bonding large areas that have to withstand high loads. But even if you want to repair ABS plastic, an epoxy resin adhesive is the tool of choice.

There are several epoxy adhesives on the market. We tested several and chose our favorite: the Gorilla brand’s two-part epoxy syringe. This is a strong and permanent adhesive that cures quickly and will dry to a clear finish.

- Strong, permanent, fast, and gap-filling epoxy glue

- Cures quickly, dries, clear, and is great for multi-surface application

- For tough repairs requiring a durable bond and solvent resistance

This two-component epoxy-based adhesive offers the user a variety of advantages. Although, as with all products, it has some disadvantages too.

PROS

- Durable and long-lasting

- Quick to cure

- Gap-filling

- Solvent-resistant

- Easy to use

- Great for several surface applications

- Good value for money

CONS

- Difficult to dispense equal amounts from both compartments

- Can be messy to work with

Apart from these disadvantages, Gorilla’s two-part epoxy ABS adhesive receives a glowing recommendation.

Special ABS Plastic Adhesive

In addition to two-component epoxy adhesives, special adhesives for ABS plastic are also available. These can be used to repair ABS plastic, but also to bond it to other materials. Such special adhesives are based on solvents and are well suited for large-area bonding.

- High-strength solvent cement with low VOC for bonding acrylic

- Fast setting with a working time of 5 - 6 minutes

- Bonds rigid PVC, ABS, styrene, butyrate, and polycarbonates

One such special adhesive is the acrylic plastic adhesive cement belonging to the Scigrip brand, which creates a very stable bond between different substrates in a short time.

PROS

- High-strength

- Creates a tough, reliable bond

- Sets quickly

- Dries clear

- Generous working time of 5 to 6 minutes

- Low VOC levels

- Available in a variety of sizes according to your requirements

- Great value for money

CONS

- Usage requires a learning curve

- Consistency is a little too thin

For ABS, the Scigrip acrylic plastic cement is one of the best solvent-based ABS adhesives, which is why we are highly satisfied with it and can recommend it.

Superglue for ABS

Superglue is actually the standard adhesive that everyone should have in the house. It is especially ideal for small and selective bonding, as it hardens quickly and usually comes in a handy tube with a small dispensing tip.

Superglue is based on cyanoacrylate and bonds many different materials permanently and with high strength. Even bonding ABS with metals is no problem. As with most adhesives, care should be taken to ensure that the surface is free of grease and oil and that the substrates are thoroughly roughened before the bonding process begins. The use of a suitable primer is also advisable if the adhesive bond is to be durable and stable.

- Two-part system with activator to prime the surface

- Develops tremendous strength with just one drop

- Slanted felt tip for precision

A superglue that produces high-strength bonds in the shortest possible time is Loctite’s Super Glue Plastics Bonding System, which comes with both a superglue and an activator to ensure the strongest possible bond.

PROS

- Comes with glue and activator for maximum adherence

- Bonds tough plastics such as PE, PP, and PTFE

- Great strength with just one drop

- Weatherproof

- Sets instantly

- Dries to a transparent finish

- Easy to use

CONS

- Small quantity of glue

- Poor felt tip design

Loctite’s superglue set is ideal for all kinds of plastics, even tough-to-bond ones such as PP and PE. This is why it receives a crystal-clear recommendation from us.

High-Performance ABS Adhesive Tape

Nowadays, high-performance adhesive tapes are also available, with which you can bond ABS plastic. Bonding different materials is usually no problem, but a primer should be applied first to surfaces that are difficult to bond. This is also recommended for ABS.

The handling of such high-performance adhesive tapes is very simple, as it is similar to that of normal adhesive tape. A major advantage is the fact that no unsightly adhesive seams or bulges can occur, caused by adhesive that has been applied too thickly and is swelling out. Care must be taken when bonding between plastics that have not been pretreated. Under no circumstances should such bonds be subjected to excessive stress.

- Eliminates drilling, grinding, refinishing, screwing, welding, and clean-up

- Double-sided, pressure-sensitive adhesive bonds on contact

- Long-term durability with no unsightly rivet heads or weld marks

At this point, we would recommend the 3M VHB heavy-duty mounting tape for ABS and other materials, which has many qualities:

PROS

- Removes any need for preparatory or refinishing work as well as cleaning

- Firm foam construction allows for excellent strength

- Double-sided adhesive bonds are pressure-sensitive, allowing for immediate adherence

- Long-lasting and durable

- Quick and easy to use

- Almost invisible

- Water- and moisture-resistant

- Bonds to a wide variety of materials

- Great value for money

CONS

- Not ideal for porous surfaces

For larger areas, the easy handling as well as the very stable adhesive bond that the 3M heavy-duty adhesive tape provides are huge bonus points. Therefore, we greatly recommend it at this point.

Practical Applications of ABS Adhesives

ABS adhesives can be used especially in the home when various objects need to be repaired. For example, if your child likes to play with plastic bricks, it is fairly certain that something will break at some point.

Our recommendations for ABS adhesives prove that toys do not always have to be bought new right away, because with these adhesives, quick repairs to building blocks or play figures are child’s play. However, you should make sure that your child does not put the repaired toy in their mouth.

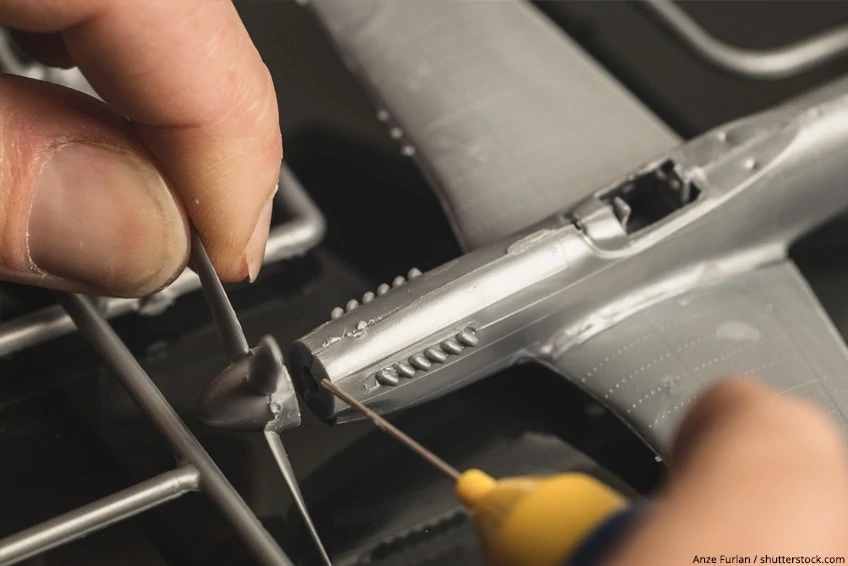

For model making, an ABS adhesive with a fine dispensing tip is particularly advisable, as this often requires a great deal of dexterity. A good ABS plastic adhesive makes it easy, for example, to attach decorative elements in model-making or to assemble figures.

Cracks in ABS cladding of household items can also be repaired quickly and conveniently with the right adhesive.

Instructions for Gluing ABS

ABS plastic bonding requires some preparation. Have the required materials ready and on hand and use protective equipment. The following materials are needed:

- Protective clothing, including a beathing mask, nitrile gloves, protective goggles, and long-sleeved clothing if necessary.

- The substrates

- The ABS plastic glue

- Sandpaper

- Solvent, for example acetone

- A lint-free cloth

Now, the surface preparation can begin.

Preparatory Work

- First, a thorough surface treatment of the substrates is carried out. To do this, clean them and allow them to dry completely. They must no longer be damp, otherwise the adhesive result will be impaired!

- Now, carefully roughen the surfaces to be bonded using the sandpaper. Take the sandpaper and drag it several times in one direction over the surface. This optimizes the adhesion of the ABS adhesive.

- Then, use the acetone and a lint-free cloth and degrease the surface. Be sure to use gloves for this step, otherwise the finger grease may reattach to the substrates and affect the adhesive result.

The Actual Bonding Process

- Once the substrates are completely dry again, you can start with the actual gluing work. Apply the ABS adhesive on one side in thin beads. Be careful not to apply too much adhesive, otherwise unsightly beads will form at the glue line.

- After applying the adhesive, press the surfaces to be bonded firmly together. Fix the substrates if necessary. Immediately absorb any escaping adhesive with a paper towel or lint-free cloth.

Curing and Loading of the Joints

- Wait for the ABS plastic adhesive to cure. Follow the manufacturer’s instructions and give the substrates a little more time rather than too little.

- If the bonding work has been carried out correctly and the curing time has been observed, the result will be a highly loadable bonded seam. Please also refer to the manufacturer’s data sheet to find out how high the load may actually be.

Rework

- After the curing phase of the ABS adhesive, the glued seam can be machined.

- You can also paint over the glued seam without any issues.

Safety Instructions

Working with epoxy resin and other similar adhesives involves some safety risks. Make sure that your skin and eyes do not come into contact with the ABS adhesive. For safety, wear long-sleeved clothing, safety glasses, nitrile gloves, and a respirator. In addition, the work area should be well ventilated.

If contact should nevertheless occur between the ABS adhesive and your eyes or mouth, wash them out thoroughly with lukewarm water immediately and consult a doctor without delay. Take the data sheet with you so that the doctor can get an idea of the ingredients. Furthermore, observe all the manufacturer’s information on processing and the safety instructions.

Bonding ABS plastic is like child’s play when you use the right adhesive. Just follow our ABS adhesive recommendations and our instructions, as then nothing can go wrong!